I’ve seen many confident first-time buyers end up frustrated when rigid boxes(https://packzino.com/custom-rigid-box/) arrive with flaws they didn’t expect. And some brands delay product launches for weeks because small packaging flaws hurt their reputation..

Mistakes to avoid when ordering custom rigid boxes include wrong materials, poor finishing, miscalculated sizes, unclear lead times, weak quality control, and neglecting logistics.

In our factory, even a 0.3 mm difference in board thickness can decide whether a box feels luxury or budget. Let’s uncover the common pitfalls and how to avoid them.

Why Do Many Buyers Choose the Wrong Materials for Rigid Boxes?

We often meet startups choosing 1.2 mm grayboard to save $0.10 — but the lids bend under product weight.. The wrong choice makes boxes fragile and lowers the premium feel.

Choosing incorrect board thickness or surface paper leads to weak structure and poor shelf presence. Always match material with product weight and market expectations.

Rigid Box Material Thickness Comparison

Rigid boxes are valued for strength and luxury appeal. Yet I often meet buyers who ask for “the cheapest option” without knowing paperboard thickness standards 1. A 1.2mm gray board may save cost, but it collapses easily under heavy skincare jars. On the other hand, a 2.5mm board with wrapped art paper provides the firm touch premium brands expect.

When choosing materials, buyers must balance cost, durability, and brand identity. For example:

| Board Thickness | Best Use Case | Risk if Misused |

|---|---|---|

| 1.2–1.5mm | Light items (small candles, soaps) | Too weak for glass bottles |

| 2.0–2.5mm | Skincare jars, perfumes | Higher cost but reliable |

| 3.0mm+ | Luxury sets, wine, electronics | Heavy shipping weight |

By avoiding the mistake of underestimating material needs, buyers save themselves from broken boxes, replacement orders, and brand disappointment.

How Can Poor Finishing Choices Hurt Brand Image?

I’ve seen perfume brands cover boxes in full foil or skip finishing entirely—both look off-brand.. Wrong finishing creates either an overcomplicated look or an unremarkable box.

Improper use of hot stamping, UV, or embossing wastes cost and reduces brand consistency. Select finishes that highlight identity without distraction.

Black Finishing with Foil Stamping

Finishes elevate rigid boxes, but they must be chosen wisely. I have seen buyers request full-surface foil stamping. The result was not luxury—it was overwhelming and even peeled at the edges. On the other side, some buyers avoided finishes entirely, leading to a flat design that failed to catch attention on shelves.

The best approach is targeted finishing. Spot UV over a logo draws eyes without distracting from the overall design. Embossing adds tactile interest 2, but it should highlight key elements instead of covering the whole surface.

Here’s a quick guide:

| Finishing | Best Effect | Common Mistake |

|---|---|---|

| Foil Stamping | Luxury detail for logos | Covering too large area |

| Spot UV | Glossy contrast | Overuse reduces clarity |

| Emboss/Deboss | Tactile highlight | Too deep or wide causes cracking |

Smart finish selection saves cost and strengthens visual identity—our French candle client proved it by switching to matte + foil logo.

With 15 years of experience in the industry, I've encountered clients who request glossy products while also wanting the main logo to feature spot UV. This is not a wise choice.

The reason is that to ensure the SPOT UV ink adheres to the paper, we must use an ultra-glossy film for lamination. The end result is that the SPOT UV effect appears flat, with only a tactile embossed sensation. This is essentially a waste of money. The proper approach is to use a matte finish and apply SPOT UV only to the focal points.

What Happens When Box Size and Structure Are Not Planned Carefully?

Many send us only “50 ml bottle” data—without exact measurements, inserts won’t fit. This mistake leads to misfits and product damage 3.

Incorrect box measurements or unsuitable structures cause instability, wasted space, or high shipping costs. Accurate planning prevents these problems.

Size and Structure Comparison

Rigid boxes must fit products like a tailored suit. A skincare jar that rattles inside a drawer box feels cheap. A perfume bottle too large for its shoulder box cracks during transport. These errors often come from buyers sending only bottle volume (“50ml”) instead of precise millimeter measurements.

Structures add another layer of complexity. A magnetic closure box works for sets but wastes space for single jars. A drawer box feels elegant but needs strong inner trays.

Examples of structure use:

| Structure | Best Use Case | Pitfall |

|---|---|---|

| Magnetic Closure | Luxury gift sets | Too bulky for shipping |

| Drawer Box | Perfume, jewelry | Needs custom insert |

| Shoulder & Neck | Premium skincare | High unit cost |

We always run CAD fitting with real jars—one mm off can ruin 500 boxes.

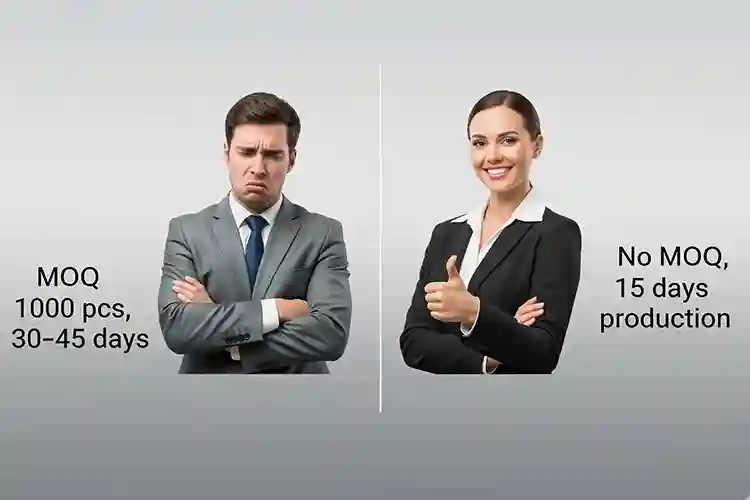

Why Do Buyers Overlook MOQ and Lead Time Issues?

Some buyers think 200 rigid boxes can finish in a week—but every piece is hand-wrapped. This mistake delays launches and misses seasonal peaks.

Not checking MOQ and production times upfront creates unmet expectations. Always confirm supplier flexibility before placing orders.

MOQ and Lead Time

I meet many buyers who believe rigid boxes are just like folding cartons—fast and easy to produce. But rigid boxes need board cutting, paper wrapping, and hand finishing. Some factories require 1000+ MOQ and 30–45 days of lead time.

When buyers discover this too late, they lose sales opportunities during holiday seasons. To avoid this mistake, ask your supplier directly:

- What is the MOQ?

- Can you support trial runs?

- How long is sample time and bulk production?

At Packzino, we solve this by offering no minimum order, 3-day samples, and 12-day production in Off-season. For many startup brands, this speed and flexibility prevents the costly mistake of missing sales windows.

How Can Weak Quality Control Lead to Costly Returns?

Some buyers trust the first sample but skip quality checks for mass production. This mistake leads to unexpected defects.

Without proper QC, boxes may arrive with color mismatches 4, scratches, or glue marks. Setting standards reduces risk and protects investments.

Printing Quality Control Inspection

Rigid boxes involve multiple steps: printing, wrapping, finishing, gluing. Each step introduces risks. Without QC, 20% of boxes may have visible flaws, yet replacing them overseas is costly.

Buyers should request three levels of quality control:

- Pre-production sample approval

- In-process QC during wrapping

- Final inspection before shipping

A common mistake is skipping the middle stage, thinking it saves time. But mid-process QC often prevents large-scale errors like misaligned logos or glue marks.

By investing in consistent QC, buyers protect brand reputation and avoid expensive replacements.

Why Is Ignoring Logistics and Packaging Safety a Serious Mistake?

. This mistake risks damage during international shipping.

Weak export cartons or lack of inner protection 5 cause boxes to collapse in transit. Safe packing ensures reliable delivery.

Shipping cartons

Rigid boxes are bulky and heavy. A container load may weigh several tons. If outer cartons are too thin or pallets are stacked poorly, boxes collapse before reaching retailers. I have seen buyers lose half their shipment due to crushed corners.

Logistics mistakes include:

- Using single-wall cartons instead of double-wall

- No waterproof wrapping during sea shipment

- No corner protection for pallets

Preventing this requires clear instructions: strong cartons, stretch wrapping, moisture barriers, and careful pallet stacking. By planning logistics as carefully as production, buyers protect their investment from transport damage.

Conclusion

Every strong brand we work with learned these lessons early—a box is the handshake your customer feels first.

Last Updated: October 23, 2025

This article was refined with new real-world production insights from Packzino’s factory team — including updated material selection tips, finishing case studies, and packaging safety examples.

We keep improving it to help small and mid-size brands avoid costly rigid box mistakes and achieve better packaging results.

-

Understanding board thickness can help you choose the right materials for your products. ↩

-

Explore how adding tactile elements can make your packaging more engaging and memorable. ↩

-

Discover the risks of inadequate packaging and how to prevent product damage. ↩

-

Learn how to avoid color mismatches that can harm your brand's reputation. ↩

-

Explore the significance of inner protection to ensure your products arrive safely. ↩