The most effective strategies to lower MOQ (Minimum Order Quantity) for custom paper bags involve minimizing machine setup time. By utilizing standard "stock" sizes, opting for digital printing, consolidating multiple SKU designs into a single run, and aligning with factory material schedules, small brands can secure orders as low as 300–500 pieces without incurring prohibitive unit costs.

For many startups and SMEs in the gift, apparel, and food sectors, ordering 300–800 bags is often a struggle. Brokers may turn you away, or prices may seem unreasonably high.

Automatic Paper Bag Machine Setup

However, from a manufacturer's perspective, the logic is simple: cost is driven by machine time, not just paper cost. In our workshop, every change in die-cut plates or paper rolls halts production for at least 30 minutes ("Make-Ready Time").

When buyers align their specifications with our factory's operational efficiency, we can significantly drop the MOQ because the production line runs uninterrupted.

Here is how you can hack the manufacturing process to get small batches at better rates.

7 Strategies to Order Small Batches Effectively

1. Utilize Standard Sizes (Stock Tooling)

Stock Paper Bag Sizes

Custom sizes require custom cutting dies (molds) 1. However, every factory has a library of "Standard Sizes"—molds that stay on their machines or are readily available.

By choosing a size from the Factory Size List 2, you eliminate the cost of creating new tooling and reduce machine setup time. This simple switch can often push the accepted MOQ down to the 300–500 range.

| Your Choice | Factory Impact | Cost Implication |

|---|---|---|

| Standard Size | No new tooling; Instant setup | Low MOQ & Fast Turnaround |

| Custom Size | New die creation; Longer setup | Higher MOQ & Tooling Fees |

2. Choose Digital Printing for Micro-Batches

For orders between 100 and 200 pieces, Digital Printing 3 is the game-changer. Unlike traditional Offset printing, Digital printing requires no printing plates and almost zero ink calibration time.

When an operator starts the digital press, the first usable sheet is ready in under three minutes. This is ideal for limited editions, new product launches, or event-specific packaging where speed and low volume are critical.

3. Leverage "Shared Material" Runs

Paper and Handle Materials

Paper mills typically sell material in massive "Jumbo Rolls." Opening a new roll for a small order is inefficient. However, our warehouse always stocks common materials like 150gsm Kraft and 230gsm White Card 4.

If your order uses a paper stock that is already running for a larger client, we can consolidate your production. By slotting your order into an existing material run, we bypass the material setup stage entirely.

Best Stock Materials for Low MOQ:

- 120–150 gsm Brown Kraft (Recycled & Virgin)

- 180–230 gsm White Kraft / Cardstock

- 190–250 gsm C1S (Coated One Side)

- 157-250 gsm C2S (Coated 2 Sides)

4. Keep Surface Finishing Simple

Complex finishes like Hot Foil Stamping 5, Spot UV, or Embossing require their own separate machine setups. For a batch of 300 bags, the waste generated during the setup of these machines can be disproportionately high.

To keep costs low, stick to one simple finish or rely on the print design itself for visual impact. If a foil logo is a must, ask if we can arrange your job on a "shared foil plate" to spread the setup cost.

5. Consolidate SKUs (Gang Run Printing) 6

Gang Run Printing

Do you have different designs for different occasions (e.g., "Holiday," "Standard," "Sale")?

Instead of ordering 500 of each separately, combine them!

As long as the bag size and material are identical, we can run multiple designs in a single production batch (often called a "Gang Run"). This allows you to reach a higher total volume (e.g., 2,000 total), significantly lowering the price per piece 6 while still getting the variety you need.

6. Plan Quarterly Production

Ordering monthly creates twelve separate setup charges a year. We advise our long-term apparel and gift clients to switch to Quarterly Planning.

By combining three months of inventory into one order, you remove two setup charges and stabilize your unit price. We can produce the batch in one go, ensuring color consistency and better economy of scale.

7. Opt for Machine-Automated Handles

Paper twist handles

Handle assembly is often the bottleneck in bag production. Premium options like Cotton Ropes or Ribbons often require manual punching and hand-threading, which drives up labor costs.

For the best MOQ and price, choose handles that can be applied by fully automated machines:

- Twisted Kraft Paper Handles

- Glued PP Cord Handles

- Die-Cut Handles (No attachment needed)

The Economics of MOQ

Why Does MOQ Exist?

To understand MOQ, you must understand the "Make-Ready" process. A standard paper bag line involves seven stages: Cutting, Printing, Lamination, Die-Cutting, Forming, Gluing, and Handle Mounting.

Every time we change a specification (width, ink, or shape), the machine must be stopped and recalibrated. This "downtime" costs money.

- The Reality: A single size adjustment can take 20–60 minutes.

- The Result: If an order is too small, the machine spends more time stopped than running.

MOQ isn't a barrier designed to block small buyers; it is a mechanism to ensure the production cost doesn't spiral out of control for you.

How to Negotiate Like a Pro

Buyer–Supplier Negotiation

Small brands can secure better terms by asking "Factory-Friendly" questions. When you show flexibility, you become a partner rather than just a buyer.

Ask your supplier these questions to unlock lower MOQs:

- "Which paper sizes are currently running on your machines this week?" (Allows you to slot into an existing run).

- "Do you have any 'leftover' stock materials I can use for a small batch?"

- "Can I combine 3 different artworks if I keep the size identical?"

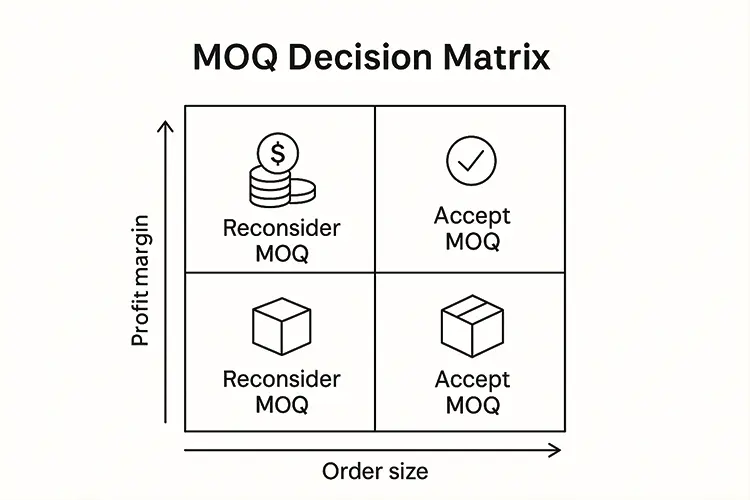

The MOQ Decision Matrix

| Strategy | Factory Efficiency Benefit | Result for Buyer |

|---|---|---|

| Use Standard Size | Zero Die-Change Time | Lower Setup Fee |

| Stocked Material | No Material Sourcing Time | Faster Lead Time |

| Digital Printing | No Plates Required | Best for <500 pcs |

| Quarterly Ordering | High Volume Run | Lowest Unit Price |

MOQ Decision Matrix

Common Questions on Small Batch Ordering

1. What is a realistic MOQ for custom paper bags?

For factory-direct orders, the realistic MOQ is 300 pieces for Digital Printing and 1,000 pieces for Offset Printing. However, by using stock sizes, we can often accommodate Offset orders as low as 500 pieces.

2. How can I reduce the cost of a low-MOQ order?

Focus on standard "stock" sizes, choose materials already in the factory warehouse, and avoid complex manual finishing (like hand-tied ribbons). Digital printing is also the most cost-effective method for orders under 500.

3. Are low-MOQ paper bags lower quality?

No. Our Quality Control (QC) standards for paper stiffness, print alignment, and glue strength remain rigorous, whether you order 300 or 30,000 pieces. The only difference is the printing method (Digital vs. Offset).

4. Which printing method is best for small batches?

For quantities between 100–800 pieces, we recommend Digital Printing to eliminate plate costs. For orders over 1,000 pieces, Offset Printing offers a lower unit price and higher color fidelity (Pantone matching) 7.

5. Can I produce multiple designs under one MOQ?

Yes. This is called "SKU Consolidation." If the bag size and paper material are identical, we allow buyers to combine multiple artwork designs into one production run to meet the MOQ requirement. Contact us to discuss your SKU Consolidation needs

Conclusion

Small brands no longer need to compromise on branding due to high volume requirements. By strategically choosing standard sizes, automated finishes, and digital production methods, you can align your needs with factory workflows. This partnership approach ensures you get high-quality custom packaging at an accessible entry point.

Ready to start? Contact our team to request our current "Factory Size List" and see how we can slot your small batch into our next production run.

-

Learn the mechanics of how custom shapes are stamped out from paper rolls. ↩

-

See examples of standard "stock" bag dimensions that require no tooling fees. ↩

-

Compare cost, speed, and quality differences between digital and offset printing methods. ↩

-

Understand what GSM means and how paper weight affects packaging durability. ↩

-

Visualize how premium finishes like foil stamping look on real custom packaging. ↩

-

Discover more factors that influence packaging costs beyond just batch size. ↩ ↩

-

Learn how the PMS system ensures your brand colors look consistent globally. ↩