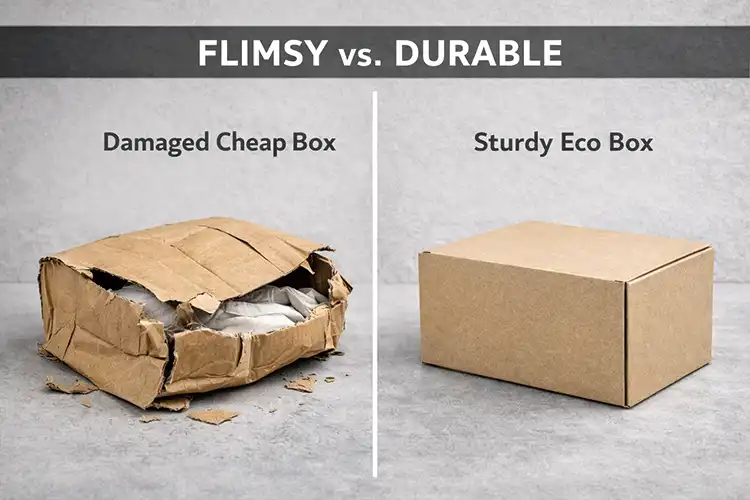

Many apparel brands want sustainable packaging, but end up with boxes that feel cheap, weak, or disconnected from their brand value.

In 2026, successful apparel packaging needs a tough skeleton. It has to stay eco-friendly while surviving the rough hands of logistics carriers without looking like a mess when it reaches the customer.

If your brand is growing and cost matters, keep reading below.

Why is sustainable packaging now a brand expectation, not a bonus?

Customers can smell fake sustainability. If you use a thin box that falls apart, they will not care about your "green" logo. They just see a brand that does not care about quality.

In 2026, apparel packaging sustainability is judged by material honesty, durability, and real-world usability, not slogans.

FLIMSY ECO PACKAGING DAMAGES BRAND TRUST

I see a clear change when I talk with apparel founders and operations teams. A few years ago, brands asked, “Can this box be recycled?” Now they ask, “Does this packaging look and feel aligned with our values?”

Sustainable packaging is no longer a marketing layer added at the end. It is part of brand credibility. Customers, especially repeat buyers, can tell when a box is designed only to look eco-friendly but fails in daily use – and recent research on unboxing trends for e‑commerce packaging 1 shows how this impacts loyalty.

In apparel, this matters more than many people expect. Clothing is emotional. Customers touch it. They store it. They reuse boxes. When sustainable packaging collapses, tears, or stains easily, the brand message breaks.

Common sustainability mistakes I still see

| Mistake | Why brands do it | Real result |

|---|---|---|

| Ultra-thin recycled board | Cost pressure | Box deformation |

| Raw paper with no testing | Eco image focus | Stains and tearing |

| Oversized boxes | Fear of fit issues | Extra carbon footprint |

| Too many components | Design-driven thinking | Harder recycling |

Sustainability fails when packaging works only on paper. It succeeds when it works in the customer’s hands – recent studies on how sustainable packaging affects consumer behavior 2 show that perception of waste and usability directly affects trust.

Which packaging structures support sustainable apparel brands best?

The wrong box shape kills your profit. We always look for ways to cut down on material weight without making the box feel like a cheap toy.

In 2026, rigid boxes, collapsible rigid boxes, and reinforced folding cartons are the most effective structures for sustainable apparel packaging.

SUSTAINABLE STRUCTURE OPTIONS

Saving space with smart engineering

Structure selection is where sustainability decisions become practical. I always start here with clients, before discussing materials or finishes.

Factory Case Study: We helped a client switch from standard rigid boxes to a collapsible rigid box structure 3, a format widely used in premium packaging to reduce volume without losing rigidity. They used to ship 200 boxes per pallet. After the change, they fit 800 boxes on the same pallet. This cut their international freight costs and carbon footprint by 75% because they stopped paying for "shipping air." It also made their last-mile delivery much more efficient for their 3PL warehouse.

Structure Comparison for Buyers

| Structure | Material Efficiency | Reuse Potential | Shipping Impact |

|---|---|---|---|

| Collapsible rigid box | High | High | Low volume |

| Standard rigid box | Medium | High | High volume |

| Reinforced folding carton | High | Medium | Low volume |

How do sustainable materials affect unboxing experience?

Eco materials that feel cheap reduce perceived value. Texture and weight matter.

In 2026, sustainable apparel packaging materials must deliver tactile quality alongside environmental benefits.

TACTILE MATERIAL TRENDS

Many brands worry that sustainable materials will weaken their premium image. This concern is valid if material selection is rushed.

Texture over plastic

Texture replaces gloss in many sustainable designs. A subtle paper grain often communicates quality better than heavy printing.

We often advise clients to use heavy embossing on raw, FSC-certified paper 4. It creates a "toothy" feel that customers associate with artisan quality. It costs less than gold foil but feels much more modern and honest.

Practical material selection guide

| Material Choice | Sustainability Value | Unboxing Feel |

|---|---|---|

| Recycled rigid board | High | Solid |

| Raw kraft paper | Medium | Natural |

| Textured FSC paper | High | Premium |

| Thin recycled carton | Low | Weak |

How can apparel brands control cost while staying sustainable?

Overspending hurts margins. Cutting too far hurts brand trust. In 2026, cost control comes from smart structure, standardization, and logistics planning.

STANDARDIZED BOX

The Standardization Hack

Cost conversations are unavoidable. I prefer to address them early and clearly. Common cost traps include custom sizes for every SKU and over-engineered inserts.

Factory Case Study: We worked with a brand selling different sizes of knitwear. They originally had 6 different box sizes, which led to high MOQs (Minimum Order Quantities). We reduced this to 2 "Master" sizes and used simple paper wraps. By ordering 10,000 units of just two sizes, their unit price dropped by 22%, and their production lead time was cut by two weeks.

Decision checklist I use with clients

| Question | Purpose |

|---|---|

| Will customers reuse this box? | Justifies rigid structure |

| Does it ship internationally? | Impacts volume design |

| Is it seasonal? | Limits overdesign |

| Is sustainability part of brand story? | Guides material choice |

How should apparel brands communicate sustainability through packaging?

Silence creates doubt. Overexplaining creates distrust. In 2026, apparel packaging communicates sustainability best through subtle cues, not heavy claims.

SUSTAINABILITY COMMUNICATION

I see brands struggle here. They want customers to know they care, but they do not want to look performative.

What works in real factory projects

Avoid large eco slogans or unverified claims. Customers trust calm confidence more than loud promises.

We recommend using a small recycling icon and a simple QR code on the bottom or inner flap. Tell the customer how to recycle the box in one short sentence. A clean, premium box speaks louder than a box covered in complex certification lists.

FAQs

Is sustainable packaging always more expensive for apparel brands?

No, because a professional redesign focuses on reducing "Total Landed Cost." While FSC-certified or recycled paper can cost 5-10% more per sheet, we offset this by optimizing the box layout. By reducing excess material and weight, our factory projects often see a 15% decrease in total packaging spend once shipping and storage fees are calculated.

What is the biggest mistake brands make with eco-friendly apparel packaging?

Prioritizing "green" aesthetics over structural burst strength. We often see brands use thin recycled board that fails in high-humidity transit. This leads to a spiking return rate because customers associate a crushed box with a low-quality product. In 2026, durability is the only way to ensure your sustainability investment doesn't end up as landfill waste due to damage.

How can apparel brands reduce shipping costs without losing quality?

By maximizing "Pallet Density" through size standardization. When you eliminate just 2cm of unused air in a box, you can often fit an extra layer of cartons on a standard shipping pallet. This increases shipping efficiency by up to 25%, directly lowering the carbon footprint per unit and reducing 3PL fulfillment fees.

Do customers really notice sustainable packaging details?

They respond to tactile density and "unboxing friction" more than slogans. Research shows that a box with a solid weight and a smooth, embossed texture creates a higher perceived value than a flimsy box covered in eco-logos. Customers associate a well-engineered opening experience with brand trust and high-end manufacturing.

How should apparel brands show sustainability without greenwashing?

Provide verifiable data through quiet design. Instead of large eco-graphics, use a small FSC license code or a QR code that links to your supply chain map. This "transparency-first" approach builds 40% more trust with modern consumers compared to unverified claims like "100% Earth Friendly."

Conclusion

In 2026, sustainable apparel packaging succeeds when structure, material, and cost work together to create honest, durable, and premium experiences.

-

Learn how unboxing and packaging design shape customer loyalty and repeat purchases. ↩

-

Understand how sustainable packaging influences consumer trust, purchase intent, and perceived brand value. ↩

-

See diagrams and detailed guidance on how collapsible rigid boxes work and when to use them. ↩

-

Learn what FSC‑certified papers are, their types, and how they support sustainable sourcing. ↩