C1S SBS 1, C2S SBS, and CCNB are the three main paperboard types used for folding cartons. Each differs in print quality, strength, cost, and sustainability.

Let’s walk through their real differences — from a factory’s point of view — so you can choose confidently without overspending.

Why Do Buyers Often Struggle to Choose the Right Paperboard?

Many buyers misjudge materials because they look similar. In printing and converting, however, the differences are huge. One paper cracks at folds 2, another prints sharper, and a third saves cost but lowers brightness.

Choosing the wrong paperboard can lead to wasted money, dull colors, or weak carton strength.

C1S SBS samples for food

I once worked with a takeway packaging customer, he instead on imported SBS. Actually, the China domestic FOOD GRADE C1S SBS can meet their needs. After testing form samples, they chose the our SBS paperboard and reduced cost by 30% without changing the look. The difference lay only in perception — not performance.

A lot of brand owners still believe imported paperboard is always better. In reality, domestic mills today reach 90–95% of the same whiteness and surface smoothness. A heavier board doesn’t always mean a better box. Overly thick paper can crack at folds, and shipping costs climb fast when weight adds up.

The smarter way is to think about the suitable one. The most expensive option isn’t always the best fit. A well-made domestic SBS, like the Sun Paper 3, Chenming Paper 3, can perform nearly as well if combined with the right printing and coating. In packaging, context always matters more than assumptions.

What Makes C1S SBS Ideal for Skincare and Food Packaging?

C1S SBS (Solid Bleached Sulfate, one side coated) offers a bright, smooth surface on one side and a natural back for gluing or laminating. It’s a reliable all-rounder for most folding cartons.

C1S SBS provides excellent print quality and stiffness while keeping costs manageable.

C1S SBS Folding Carton

For a Canadian skincare brand, we replaced imported SBS with 18PT C1S from a domestic mill. After matte lamination and embossing, the difference was invisible — but the total packaging cost dropped 28%.

Balancing Visual Appeal and Functional Strength

Every paperboard choice involves trade-offs. A thicker coating gives glossier color but can slightly weaken folds. Long-fiber pulp increases stiffness but also raises cost. Matte lamination looks elegant but reduces recyclability.

From years of production, I’ve learned that the “premium” appearance rarely comes from the base paper alone. Finishing and printing control make the bigger difference. A quality domestic C1S combined with good lamination can outperform a poorly printed imported board.

So instead of asking which material is “best,” I often tell clients to ask: which paper fits my product, my process, and my price point?

| Factor | Visual Effect | Functional Result |

|---|---|---|

| High coating weight | Glossy, sharp print | Slightly reduced fold strength |

| Long-fiber pulp | Stronger stiffness | Higher cost |

| Matte lamination | Premium texture | Reduced recyclability |

When Should You Choose C2S SBS Instead of C1S?

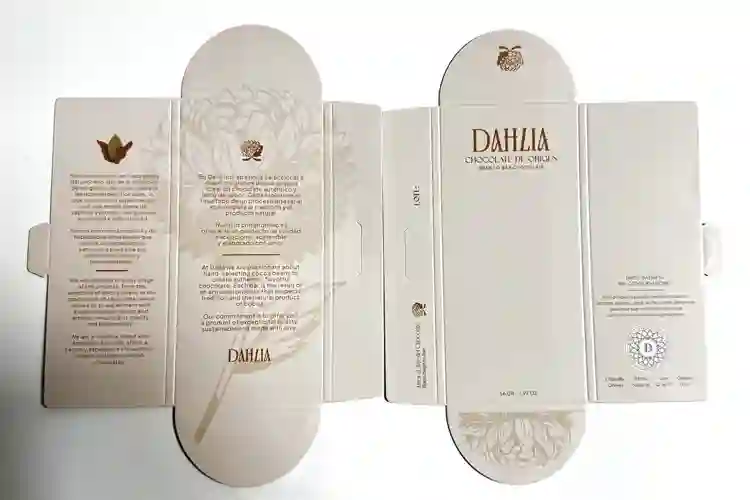

C2S SBS (two sides coated) is made for boxes where both sides matter — like perfume, chocolate, or luxury skincare. Its interior is bright white and printable, giving a clean, unified look.

C2S SBS delivers a premium feel inside and out, ideal for double-sided printing and luxury branding.

C2S SBS Dual-Side Printed Box

For a Japanese perfume line, the inner flaps needed to match the exterior color. Local C2S appeared slightly warm, so we switched to Nippon Paper’s C2S — perfect tone, but double the cost.

Is Double Coating Always Worth It?

The contrast between C1S and C2S lies mainly in purpose.

| Property | C1S SBS | C2S SBS |

|---|---|---|

| Inner Surface | Uncoated, matte | Coated, glossy |

| Printability | Excellent | Excellent both sides |

| Folding Resistance | Moderate | Strong |

| Typical Use | Skincare, food | Perfume, luxury |

| Cost | Medium | High |

C2S isn’t automatically “better”; it’s more specialized. If your customers will never see the inside of the box, that upgrade might be unnecessary. But if the interior tone and feel add value to the product, then C2S is the smarter investment.

As I often remind buyers, spend where your customers look the longest — not where they’ll never notice.

Is CCNB Still Worth Using for Cost-Effective Boxes?

CCNB (Clay Coated News Back) has a white coated surface and a grey recycled back. Many consider it low-end, but for high-volume or short-term products, it’s an excellent balance of cost and performance.

CCNB offers high stiffness, good printability, and the lowest cost among common paperboards.

CCNB Grey-Back Packaging Boxes

We once made 20,000 pet toy boxes for a European customer using CCNB. After applying glossy lamination, the grey back became invisible, and the shelf look matched SBS — at 35% less cost.

The Environmental and Economic Balance

Every material choice has two sides. CCNB is affordable, sustainable, and strong, but its brightness and texture limit its use for luxury products.

| Perspective | Benefit | Limitation |

|---|---|---|

| Economic | Low cost, high stiffness | Lower brightness |

| Sustainability | 100% recycled | Not food-contact safe |

| Print Surface | Acceptable | Not ultra-smooth |

| Branding | Good with lamination | Limited for luxury boxes |

For mass-market products or promotional packaging, CCNB performs more than well enough. The key is to use it strategically — not universally.

How Do Chinese-Made Paperboards Compare to Imported Ones?

Clients often ask whether Chinese paperboards are as reliable as imported ones. The answer is increasingly yes. The quality gap has narrowed dramatically in the past five years.

Modern Chinese mills like APP, Bohui, and Sun Paper produce SBS with brightness and stiffness close to European and U.S. standards.

Pharma-grade SBS boxes

In my experience, domestic boards now achieve 90% of imported quality while offering shorter lead times and lower MOQs — a major advantage for small and mid-size brands.

The Local vs Imported Debate

Imported paperboards still lead in certification and uniformity, but domestic options have caught up in appearance and price stability.

| Feature | China-Made SBS | Imported SBS |

|---|---|---|

| Brightness | 90–93% | 95–98% |

| Fiber Source | Mixed pulp | 100% virgin long fiber |

| Consistency | ±5% | ±2% |

| Certification | FSC, ISO | FSC, PEFC, FDA |

| Lead Time | 10–15 days | 45–60 days |

| Cost | 25–40% lower | High but stable |

Imported boards still win in absolute quality and certification, but domestic boards are flexible, quick to source, and cost-effective — making them a smart choice for growing brands.

“Made in China” now means efficiency and adaptability. When printing and color control are done right, most customers won’t tell the difference — and your bottom line will thank you.

How to Choose the Right Paperboard for Your Product?

The right paperboard isn’t the most expensive — it’s the one that matches your brand and product story. Each type serves a different purpose based on print requirements, product weight, and market positioning.

Each board type suits a different packaging goal and price range.

| Product Type | Recommended Board | Why It Works |

|---|---|---|

| Skincare / Cosmetics | C1S SBS or C2S SBS | Clean print, bright white, premium look |

| Food & Beverage | C1S SBS or CCNB | Safe, economical |

| Perfume / Luxury | C2S SBS | Double-coated, bright interior |

| Toys / Gifts | CCNB | Rigid, cost-effective |

| Pharmaceuticals | C1S SBS (FDA Grade) | Certified, hygienic |

The Three-Fit Rule

When I help clients choose, I always ask three questions:

Does this paper represent your brand image?

Will it stay strong during shipping and display?

And does it fit your price range?

Good buyers don’t chase trendy materials. They choose what works consistently, for quality, practicality, and brand identity.

Conclusion

Choosing paperboard isn’t about prestige — it’s about purpose. The right material keeps your packaging beautiful, durable, and cost-efficient.

That’s how brands grow smart — one well-chosen board at a time, contact our packaging experts.