Eco-friendly labels use responsibly sourced materials, clean adhesives, low-VOC inks, and recycling-compatible designs. A label is truly sustainable only when every component works across sourcing, printing, application, and end-of-life recovery.

Many brands want to switch to sustainable labels, but the real challenge is understanding what “eco” means in production. Not every material works on every line, and not every certification is necessary. A clear framework upfront prevents delays, misprints, and unnecessary cost.

What Makes a Label Truly Eco-Friendly Today?

Some teams focus solely on surface material, assuming “paper equals eco.” In reality, recyclability depends on how the paper, adhesive, and ink behave together during application and disposal.

A practical eco label must meet three criteria: responsible sourcing, clean separation during recycling, and compatibility with your filling or labeling process.

There are cases where compostable films 1 distort under heat tunnels, or adhesives interfere with PET recycling. These issues occur not because materials are bad—but because they were mismatched with the production environment.

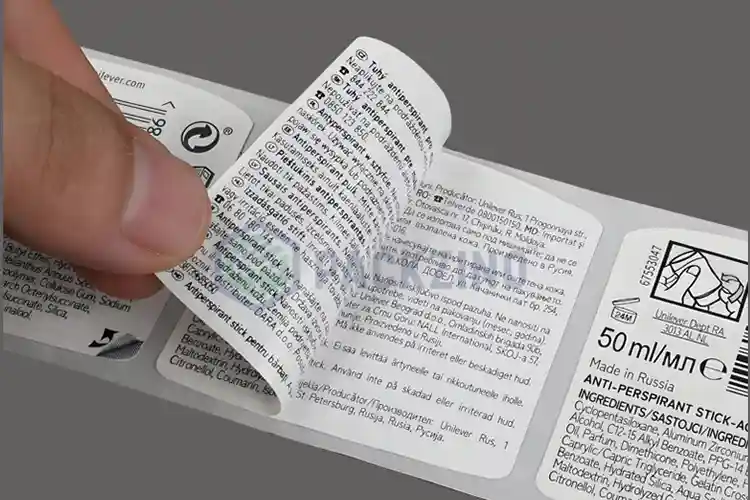

A view of common sustainable label

Material Considerations

Renewable fibers, recycled content, compostable films, and their print behavior.

Adhesive Considerations

Wash-off performance, recyclability, and resistance to humidity or heat.

Ink Considerations

Water-based inks for low VOCs; UV inks for durability; soy inks for lower petroleum use.

Recyclability Overview

| Component | Recyclable? | Notes |

|---|---|---|

| FSC paper | Yes | High compatibility |

| Recycled paper | Yes | Color variability |

| PLA film | No | Compostable only |

| Bio-PE | Yes | Depends on region |

Which Eco-Friendly Label Materials Perform Best in Real Production?

Different materials behave differently on press and during application. Recycled paper absorbs more ink, leading to darker tones. Bamboo or hemp papers can vary between batches. PLA remains sensitive to heat, making it unsuitable for longer transport or hot-fill processes.

The most stable option for most brands remains FSC-certified paper 2, balancing print quality, durability, and cost.

Natural-looking brands often prefer recycled paper, while moisture-heavy environments—like beverages or skincare—benefit from bio-based PE for stability.

Paper vs film vs eco-friendly label materials

FSC Certified Paper

Strong, stable, excellent print quality; ideal for skincare and food.

Recycled Paper

More ink absorption and darker tones; suitable for natural-style brands.

Sugarcane / Bagasse

Rough fibers; not ideal for detailed logos.

Bamboo / Hemp Paper

Renewable but inconsistent supply; higher MOQs.

Compostable PLA

Heat-sensitive; risks curling during transport.

Bio-Based PE

Durable, recyclable, and suitable for moisture-heavy environments.

Comparison Table

| Material | Print Quality | Durability | Cost | Notes |

|---|---|---|---|---|

| FSC Paper | ★★★★★ | ★★★★☆ | Medium | Best balanced option |

| Recycled Paper | ★★★☆☆ | ★★★☆☆ | Low | Natural, darker tone |

| Bagasse | ★★☆☆☆ | ★★☆☆☆ | Medium | Fibrous surface |

| PLA | ★★★☆☆ | ★★☆☆☆ | High | Heat-sensitive |

| Bio-PE | ★★★★☆ | ★★★★★ | High | Strong for bottles |

Which Adhesives and Inks Support Sustainable Labeling?

A technically “eco” label can still fail sustainability requirements if the adhesive doesn’t release during recycling or if the ink adds unnecessary VOCs.

Water-based inks offer lower emissions but lighter color density. UV inks provide durability but require more energy.

Soy inks 3 reduce petroleum content but don’t automatically guarantee greener performance.

Wash-off adhesives remain the most reliable choice for PET bottle recycling 4, while water-based adhesives perform well on paper surfaces but may weaken on films under humidity.

Film label printing clarity in production

Adhesive Types

| Type | Benefit | Limitation |

|---|---|---|

| Water-based | Low VOC | Lower bonding on films |

| Wash-off | PET recycling compatible | Higher cost |

| Removable | Easy to apply and remove | Weak under humidity |

Ink Types

- Water-based inks: low VOC, lighter color density

- UV inks: strong durability, higher energy requirement

- Soy inks: lower petroleum content, not automatically “greener”

Which Eco Certifications Can Buyers Actually Trust?

Certifications help validate sourcing, recyclability, or compostability—but not every label needs them.

Retail programs, export markets, and product category often dictate which certifications matter.

FSC works for most paper labels, while ISO 14021 [^5] helps support environmental claims. Compostable certifications like OK Compost or BPI are only relevant for brands planning to use compostable packaging from end to end.

Common certifications for sustainable labels.

Certification Breakdown

| Certification | Meaning | Industry Use |

|---|---|---|

| FSC | Sustainable forestry | Skincare / food |

| PEFC | Forest chain-of-custody | Global brands |

| OK Compost | Compostable verification | Food packaging |

| BPI | North America composting | Coffee / bakery |

| USDA BioPreferred | Bio-based content | Supplements |

| ISO 14021 | Environmental claims | All industries |

Which Industries Benefit the Most From Eco Labels?

Different industries place different demands on labels.

Skincare requires premium print definition.

Food and bakery products lean heavily on compliance.

Coffee packaging often needs heat resistance.

Supplements value clean, stable labeling for bottling lines.

Apparel brands look for recycled content to reinforce their eco story.

labels work in different industries

Industry Table

| Industry | Best Material | Notes |

|---|---|---|

| Skincare | FSC / Bio-PE | High print clarity |

| Food | Compostable / FSC | Regulation-driven |

| Coffee | PLA / Bio-PE | Heat matters |

| Supplements | FSC | Clean, simple |

| Apparel | Recycled paper | Eco story-driven |

What Mistakes Do Buyers Commonly Make When Choosing Eco Labels?

Eco choices often fail not because materials are poor, but because they are mismatched with real production conditions.

Recycled papers mute colors.

PLA curls under heat.

Adhesives can contaminate recycling streams.

Bio-based materials may face supply instability.

The safest approach is testing materials on your actual production line before committing to scale.

Typical issues when materials are mismatched

Common Mistakes

- Choosing recycled paper without considering ink absorption

- Using PLA where heat exposure is high

- Assuming compostable equals recyclable

- Forgetting adhesive compatibility for PET recycling

- Ignoring supply-chain stability for bio-based materials

Frequently Asked Questions (FAQ)

FAQ 1: Do eco-friendly labels cost more than standard labels?

Eco-friendly labels can cost 10–25% more depending on fiber type, printing method, and adhesive requirements. Pricing varies by region and supply chain stability. Choosing certified paper instead of compostable films often provides a more affordable and reliable balance.

FAQ 2: How do I choose the right eco label for my product’s environment?

Match your label to the conditions it will face—moisture, heat, friction, and filling speed. Paper suits dry goods, while Bio-PE performs better on refrigerated or squeezable packaging. Testing samples on your actual production line avoids costly failures.

FAQ 3: Can eco-friendly labels run on automatic labeling machines?

Most eco materials run well on automatic equipment, but recycled fibers and compostable films may require slower speeds or adjusted roller pressure. Consistency in thickness and coating is key. Verifying machinability before mass production prevents alignment issues.

FAQ 4: Do small brands need certifications to claim sustainability?

No. Most small brands don’t need full certification unless demanded by retailers or export markets. Using responsibly sourced materials and publishing transparent claims under ISO 14021 guidelines is often enough for regulatory compliance and consumer trust.

FAQ 5: How can brands reduce the environmental impact of labels without changing materials?

Brands can lower impact by optimizing label size, reducing ink coverage, using water-based varnishes, and choosing wash-off adhesives for PET systems. Good design choices often deliver bigger sustainability gains than switching to expensive specialty materials.

Conclusion

Sustainable labeling only works when the material, adhesive, ink, and certification align with your production environment. When these elements fit together, you avoid delays, control cost, and present a credible eco commitment to your customers.

-

Understand the technical differences between compostable and biodegradable materials to avoid selection errors. ↩

-

Verify the specific meaning of different FSC labels to ensure your product meets chain-of-custody standards. ↩

-

Compare the pros and cons of soy inks versus traditional inks to see which fits your sustainability goals. ↩

-

Learn more about SmartSolve materials in PET Recycling applications.

[^5]: Review international standards for making self-declared environmental claims to avoid legal risks. ↩