Many brands assume paper bags are inexpensive 1—but from our production experience, small details can quickly double the total cost.

We’ve seen a $0.20 quote turn into $0.50 once setup, sampling, and shipping were included.

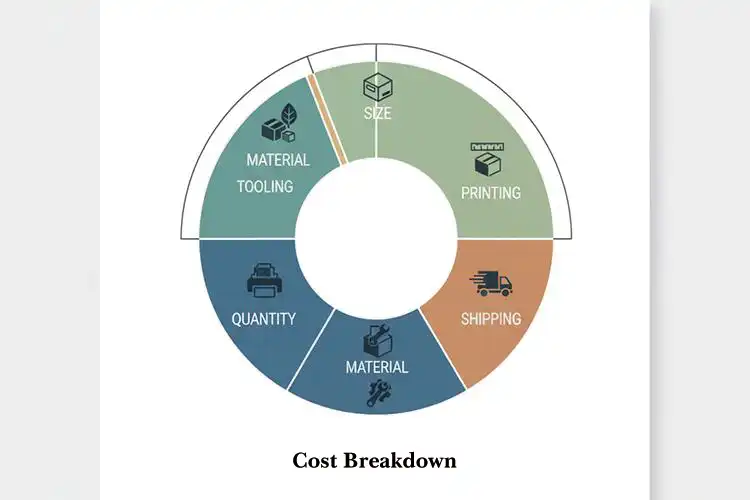

The cost of a custom paper bag depends on four main factors: paper material, printing method, order quantity, and often-overlooked extras like setup or freight.

If you’ve ever compared suppliers and found huge price gaps, this guide explains why—and how to keep control from the start.

Why Do Prices for Custom Paper Bags Vary So Much?

Prices for custom paper bags can differ by 30–50% 2, depending on material type, printing, finish, and order volume.

Many buyers feel confused when two similar quotes show different totals.

From a manufacturer’s view, it’s not about pricing tricks—it’s how small specification changes affect setup, labor, and materials.

Material and handle variations for custom bags.

We often receive RFQs that look the same but aren’t.

One may specify kraft paper with one-color print, another coated paper with matte lamination—the difference can easily reach 40%.

💡 Tip from production: always compare “like for like.”

Aligning specifications early keeps your quote accurate and transparent.

What Are the Main Factors That Affect Paper Bag Cost?

Five key elements shape paper bag pricing: paper quality, bag size, printing method, handle type, and order quantity.

Many buyers think paper type decides everything, but cost depends on how these factors interact.

The right combination gives both strength and appearance without unnecessary spend.

Key cost factors in custom paper bag pricing.

When we help clients choose specs, we start with one question: What’s inside the bag?

A bakery doesn’t need the same thickness or coating as a luxury skincare brand.

Choosing fit-for-purpose specs avoids waste and improves consistency.

Material, Size & Printing Choices That Shape Cost

1. Material

- Brown Kraft Paper – Eco-friendly 3, affordable, and ideal for natural branding.

- White Kraft Paper – Clean surface, better color reproduction, slightly higher cost.

- Coated Art Paper – Premium feel, supports full-color CMYK or foil 4.

- Recycled Paper – Sustainable but lower strength.

2. Size

- Larger bags use more paper and increase waste.

- Expect 10–15% higher cost for every 5 cm increase in width or height.

3. Printing

- Digital printing fits small runs under 500 pcs.

- Offset lowers cost for larger runs.

- Add-ons like foil or embossing add setup and plate costs.

| Example | Bag Size | Material | Printing | Quantity | Estimated Cost/Bag |

|---|---|---|---|---|---|

| Small kraft bag | 20×25×10 cm | 150 g kraft | 1-color logo | 1000 pcs | \$0.20–\$0.25 |

| Medium matte bag | 25×30×12 cm | 200 g art paper | CMYK full print | 2000 pcs | \$0.35–\$0.40 |

| Luxury gift bag | 30×40×12 cm | 250 g coated | CMYK + foil logo | 5000 pcs | \$0.55–\$0.70 |

What Hidden Fees Do Most Buyers Overlook?

Hidden fees in paper bag production 5 often come from setup, sampling, freight, and design or color changes.

This is where most small brands get caught off guard.

A quote may look simple—but the total grows as new steps appear in real production.

Hidden Fees Breakdown

For instance, a client once requested kraft bags at \$0.25 each.

After sample courier, color correction, and artwork adjustments, the final cost reached \$0.38 per bag.

The price wasn’t inflated—it just covered steps that hadn’t been discussed upfront.

| Fee Type | Description | Typical Range |

|---|---|---|

| Setup / Plate Fee | Printing setup or plate charge | \$30–\$100 |

| Sample / Prototype | Pre-production proof | \$20–\$50 |

| Color Adjustment | Brand color calibration | \$10–\$30 |

| Freight / Shipping | Local or international transport | Variable |

| Rush Production | Lead time under 7 days | +10–30% |

| Storage / Inventory | Holding finished bags | \$5–\$15 per week |

| Design Correction | Fixing non-print-ready files | \$15–\$40 |

💡 Advice: Always ask for a cost-inclusive quote that lists what’s covered—this single step prevents 90% of cost surprises.

Real Example: Simple vs Premium Paper Bags

A basic kraft bag may cost \$0.25, while a premium laminated one can reach \$0.70—mainly due to paper weight, finishes, and printing complexity.

Two similar bags can look the same online but differ drastically in production.

Simple kraft paper bag for retail use

A skincare brand ordered 5,000 gift bags 6:

- A: 180 g kraft, 1-color, twisted handles — \$0.28/unit

- B: 230 g white kraft, CMYK, matte lamination — \$0.42/unit

- C: 250 g coated, CMYK + gold foil, cotton handles — \$0.65/unit

| Version | Paper Type | Printing | Handles | Finish | Cost/Unit |

|---|---|---|---|---|---|

| A | Brown Kraft | 1-Color | Twisted | None | \$0.28 |

| B | White Kraft | CMYK | Flat Paper | Matte | \$0.42 |

| C | Coated Paper | CMYK + Foil | Cotton Rope | Matte + Foil | \$0.65 |

The client chose Version B—a balanced design that kept visual appeal while saving 35% versus the luxury option.

Sometimes, smart selection—not cheaper material—makes all the difference.

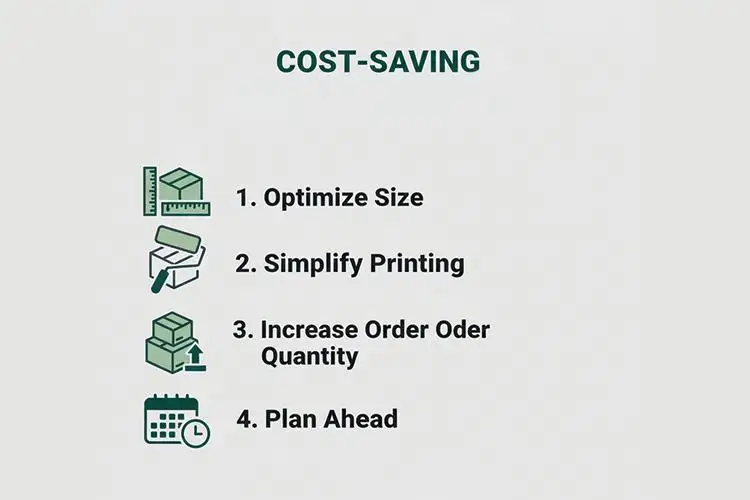

How to Save Money Without Hurting Your Brand Image?

To reduce cost, simplify design, optimize quantity, use stock sizes, and plan production early to avoid rush fees.

We often remind new brands that saving doesn’t mean cutting quality.

The smartest projects reduce waste and steps, not visual impact.

Cost-Saving Strategies

1. Simplify the Design

Skip excessive foiling or lamination—clean design prints faster and looks modern.

2. Match Quantity to Use

Order just above MOQ to access discounts but avoid dead stock.

3. Use Standard Sizes

Reuse factory dies to save 10–20% in tooling and material.

4. Combine Orders

Group SKUs to share plates and printing setup.

5. Plan Ahead

Avoid rush production and courier surcharges during peak months.

| Strategy | Why It Works | Savings Potential |

|---|---|---|

| Simplify Printing | Fewer colors = lower setup | 10–15% |

| Use Stock Sizes | Reuse factory die | 5–10% |

| Order in Bulk | Spread fixed costs | up to 40% |

| Combine SKUs | Shared plates | 5–10% |

| Avoid Rush Orders | No overtime fees | 10–25% |

💡 Factory note: planning early always costs less than fixing late.

Common Questions About Custom Paper Bags

How much do 100 custom paper bags cost for small brands?

For small runs, 100 custom paper bags usually cost $25–$40 total, depending on paper type and printing.

Digital printing is cheaper for low quantities, while offset becomes cost-effective above 500 pcs.

Learn more about small-order pricing on our Custom Paper Bags page.

What is the minimum order quantity (MOQ) for custom printed paper bags?

At PACKZINO, the MOQ starts from 100 pieces, ideal for startups and small batch packaging.

Many factories require 500–1000 pcs, so confirming MOQ early avoids hidden setup fees.

You can check lead time and MOQ details on our Contact Us page.

Which paper type is best for skincare or cosmetic packaging bags?

White kraft paper or coated art paper offers a clean, premium look for skincare brands.

Kraft paper suits eco-friendly brands, while coated art paper supports vivid CMYK printing.

See material choices on our Custom Cosmetic Packaging page.

Are custom paper bags eco-friendly and recyclable?

Yes, kraft and recycled paper bags are fully recyclable and biodegradable.

For brands targeting sustainability, FSC-certified kraft paper is the best option.

Explore more options on our Eco-Friendly Packaging Boxes page.

How long does it take to produce custom paper bags?

Standard production takes 12–15 days, plus 3–5 days for sample approval.

Rush production under 7 days is possible with an express fee.

How can I reduce paper bag costs without lowering quality?

Simplify printing, reuse standard die sizes, and plan early to avoid rush fees.

Ordering 500+ pcs can reduce unit cost by up to 40%.

See more cost-saving tips on our Folding Carton Packaging Cost Guide.

Can I order different sizes in one production run?

Yes. Grouping SKUs of similar width and height allows shared plate setup, saving 10–15% on printing costs.

Conclusion

Paper bag pricing depends on the details—material, size, printing, and timing.

Brands that plan ahead spend smarter and avoid hidden costs.

That’s why we share these insights—to help small and growing brands make informed, confident packaging decisions.

-

See global market data showing actual production costs and growth trends. ↩

-

Understand how supply chain and labor cost create 30–50% price gaps. ↩

-

Learn about recycling rates and carbon footprint of kraft paper packaging. ↩

-

Compare print quality and color accuracy between coated and kraft paper. ↩

-

Identify hidden production costs like setup, freight, and plate fees. ↩

-

See real brand examples comparing kraft and laminated paper bag costs. ↩