For many small brands, the first quote looks fine—until hidden fees show up later. Suddenly profits shrink and launch dates slip.

Custom corrugated boxes typically cost between $0.25–$2.00 per unit 1, depending on material grade, size, printing, quantity, and logistics.

Once you know where each dollar goes, it’s much easier to plan your budget and avoid surprises later. Let’s break it down step by step.

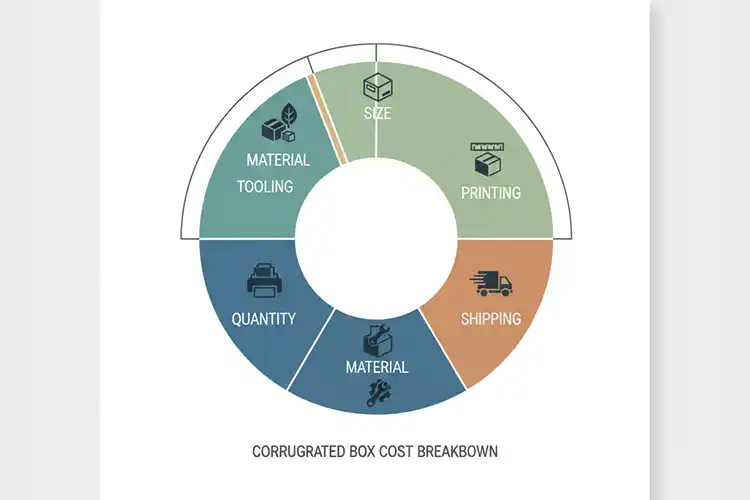

What Are the Main Cost Factors in Custom Corrugated Boxes?

Cost Breakdown Overview

Most of your cost comes down to a few things: the paper grade, the size of the box, how it’s printed, how many you order, and of course shipping. These are the levers you can actually control.

For many small brands, the first quote looks fine—until hidden fees show up later. Suddenly profits shrink and launch dates slip.

Most buyers think cost is only about cardboard weight and printing. In fact, several hidden elements drive price. Material grade and flute type 2 decide strength.

Box size influences board usage. Printing and finishing add setup costs. Quantity changes unit cost dramatically. Design and tooling may add cutting die charges. Shipping is another significant portion.

Example Cost Components Table

| Factor | Impact on Cost | Buyer Note |

|---|---|---|

| Material grade | +$0.05–$0.30 | Higher flute = stronger & more expensive |

| Box size | Direct impact | Larger boxes = more board = higher price |

| Printing method | +$0.10–$0.50 | Flexo cheaper; digital better for short runs |

| Quantity (MOQ) | Unit cost drops | Higher volume = lower per-box cost |

| Tooling fees | One-time $50–$300 | Avoid with standard styles |

| Shipping | Varies widely | Optimize size to cut freight |

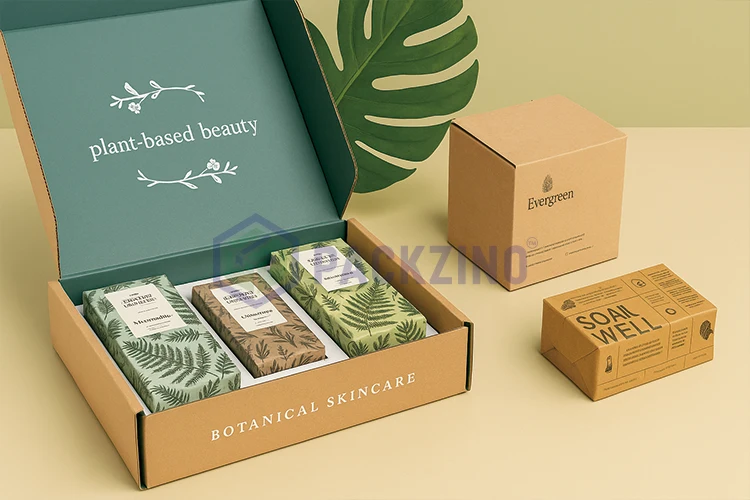

Buyers often underestimate how each factor interacts. For instance, a small luxury skincare brand might choose E-flute board for elegance. However, adding full-color digital printing plus matte lamination could double per-unit cost compared to plain kraft.

When MOQ is low, setup costs are spread over fewer units, pushing the unit price even higher. Smart buyers work with suppliers early to balance specifications with budget.

Skincare corrugated mailer boxes

A professional supplier will suggest a more suitable corrugated material ,according to products and box size. For example, a corrugated tab lock roll end tuck box is about 30X20X4CM, and the client want to be B flute, but in fact, with a height of 4CM, E flute is the best choice. Reinforcing E flute material is enough to protect the product.

This small change also cuts international shipping. On average, one carton can save around 13% in freight.

What Hidden Costs Do Buyers Overlook?

Hidden Costs Breakdown

Hidden costs include sample fees, rush production surcharges, inner inserts, and last-mile delivery charges.

Many buyers ignore small line items that later eat profit. Tooling fees for custom die-cuts 3 often surprise first-time customers. some supplier have the rush orders extra, about 20–30% extra.

Inserts for product protection may not be included in initial quotes. Freight surcharges, customs clearance, and delivery 4 to multiple warehouses also inflate costs.

For small brands, hidden costs sting the hardest. One Canadian startup thought they got a great deal on display cartons for Christmas. But when they had to switch to air freight to meet launch dates, the ‘cheap’ order ended up costing almost twice as much.

This story shows why buyers should ask suppliers to disclose full landed cost upfront, including tooling, shipping, duties, and taxes. Transparent quotes avoid disputes and help brands forecast margins correctly.

A supplier who gives you an ‘all-in’ number upfront is usually the one you can rely on. If the quote feels vague, it often means you’ll see surprises later.

How Can Buyers Reduce Corrugated Box Costs?

Cost Reduction Tips

Ways to reduce costs include optimizing size, simplifying printing, increasing volume, and planning ahead to avoid rush fees.

The easiest way to save is to reduce box size to cut board usage and freight. Avoid unnecessary coatings or complex die-cuts. Order slightly larger volumes to lower per-unit cost. Work with suppliers offering no MOQ options to test designs in small batches. Plan at least 12–15 days before product launch to avoid paying for expedited production.

FAQs on Corrugated Box Pricing

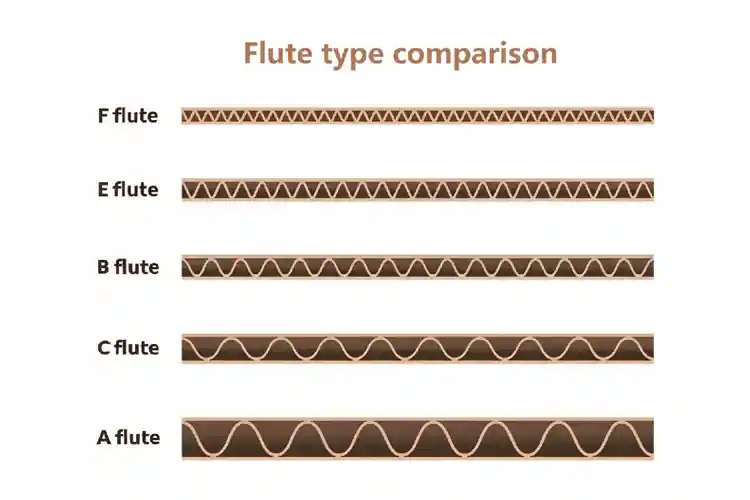

Corrugated flute type comparison

FAQs cover cheapest options, printing costs, MOQ flexibility, and lead times.

-

What is the cheapest corrugated box option?

The cheapest option is a plain kraft RSC (regular slotted carton) with single-color flexo printing.

This style uses the least material and simplest print, making it the go-to choice for shipping cartons or budget packaging. -

Will printing make my boxes more expensive?

Yes. For orders under 1000 units, custom printing usually adds $45–70 depending on box size and print method.

In practice, a small run with full-color or lamination can quickly raise per-unit cost, so simple designs save money. -

How can small brands order without high MOQ?

Small brands can order from suppliers offering no-MOQ or 100-unit trial runs.

This way, startups can test box designs in small batches before investing in large volumes. -

What’s the typical lead time?

Lead time is about 3 days for samples and 12–15 days for bulk production.

Planning a couple of weeks ahead helps avoid rush fees and unexpected shipping delays. -

How do I pick the right flute type 5 for custom mailer boxes?

E-flute is the best choice for most custom mailer boxes, balancing print quality and strength.

For very small or lightweight items, F-flute works well; larger products often need B- or C-flute for added protection.

Since 2019, I’ve worked with skincare startups, food brands, and e-commerce sellers—each with their own box styles and materials.

If you’re not sure which box type fits your product best, feel free to reach out—I’m happy to share practical advice from past projects.

Conclusion

The cost of a custom corrugated box isn’t just one number—it’s a mix of choices. When you understand those choices, you can cut waste, dodge hidden fees, and work with suppliers in a way that builds real trust.

Update Log

2025-10-02 – FAQ section rewritten with snippet-friendly answers and clear buyer notes (MOQ, lead time, printing costs).

2025-10-02 – Introduction and conclusion refined to highlight practical value for small and growing brands.

2025-10-02 – Cost examples updated with realistic scenarios (E-flute vs. B-flute choice, Canadian startup shipping case).

2025-10-02 – Overall language and structure improved for readability and stronger buyer relevance.

📌 We keep this guide regularly updated so brands can rely on it for transparent insights when budgeting and sourcing corrugated boxes.

-

Learn real-world cost breakdowns for corrugated boxes across sizes and thicknesses to benchmark your own quotes. ↩

-

Understand how different flute types (E, B, C, etc.) affect box strength, thickness, and cost. ↩

-

See how tooling and die-cutting fees are calculated and why they can add significantly to your box cost. ↩

-

Learn how customs fees, inspections, and paperwork increase landed costs when importing your packaging. ↩

-

Find expert recommendations for choosing flute types in mailer boxes based on weight, print quality, and cost. ↩