Pet treat packaging often fails because brands overlook food safety, fiber strength, and moisture control.

Packaging fail on the shelf not because of bad design, but because the oil from a simple chicken strip soaked through the bottom in 48 hours, or the box crushed under a pallet due to weak grain direction.

Pet snack brands face similar issues each year. Continue reading below for more reliable packaging choices.

Why does choosing the right packaging material matter for pet treats?

Pet treats contain oil, moisture, and natural ingredients. Wrong materials cause grease stains, warping, microbial risks, and customer complaints.

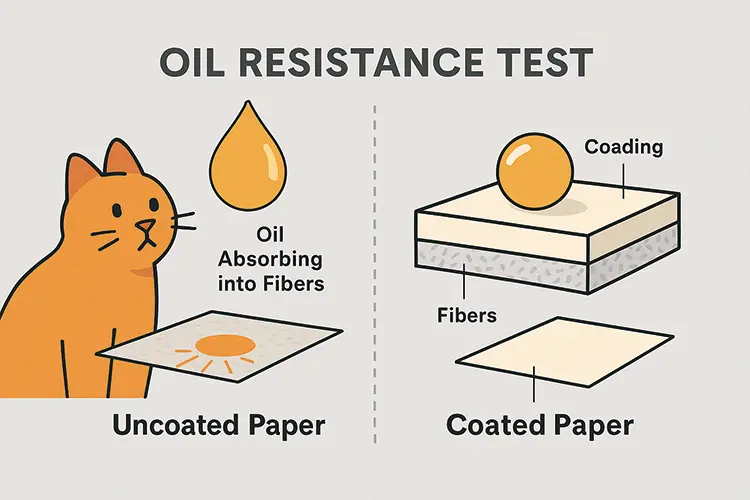

In the factory, we don't just ask “is it safe?”; we check the Kit Value oil resistance testing method1 to assess how well the paper handles oily food contact.

If you put a high-fat duck chew in standard 300gsm paper, you will see a grease halo within a week. You need a physical barrier, not just strong paper.

OIL effect on Coated vs Uncoated Paper

To understand more about structural choices, see our

custom pet packaging boxes — built specifically for oily and moisture-sensitive pet treats.

I once worked with a Canadian pet snack brand who used standard white carton for chicken jerky treats. Boxes warped after two weeks because the product released natural oil. We switched to PE-coated kraft with inner pouches. Their packaging held clean, dry, and stable for three months.

How oil affects paper stability

Pet treats with high oil content transfer grease directly into paper fibers.

Without proper coating, surfaces will stain and soften.

How moisture affects microbial risk

Moisture inside a closed box can cause mold.

Paper without barrier coating absorbs moisture and accelerates spoilage.

Failure Table

| Treat Type | Typical Issue | Wrong Material Cause |

|---|---|---|

| Chicken jerky | Oil staining | Non-coated carton |

| Soft chews | Warping | Weak fiber & moisture |

| Fish snacks | Odor leakage | No barrier layer |

| Mixed treats | Collapse | Low GSM paper |

Is kraft paper reliable for natural and oily pet treats?

Kraft is strong, natural-looking, and oil-resistant when paired with coatings.

Unlike recycled greyboard that cracks at a 90° fold, virgin kraft fiber maintains structural tension — aligning with FSC-certified virgin fiber standards2.

That’s why for a 500g bag of heavy dog bones, 350gsm brown kraft acts like a suspension system.

Pet brands wanting a deeper material comparison can also review our

folding carton and paperboard packaging options.

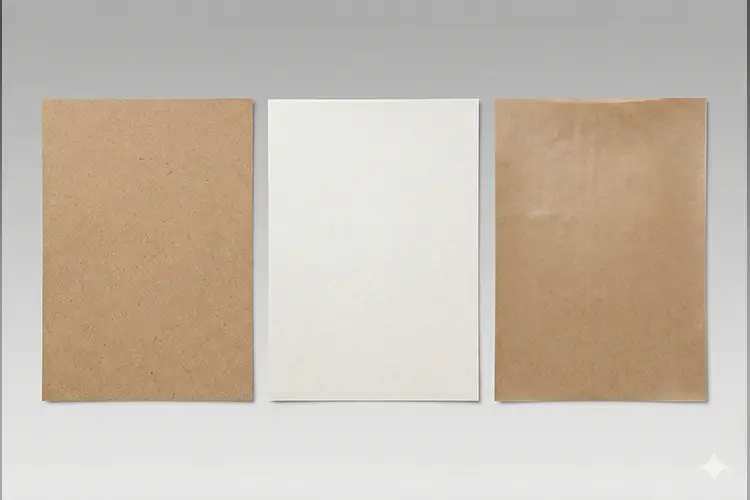

Kraft, White and PE-Coated Paper Comparison

One Singapore brand used uncoated kraft for salmon treats, and the box began to show visible grease staining within 10 days. After switching to PE-coated kraft, staining stopped completely.

This illustrates that kraft can perform very well with oily foods, but typically only when supported by a functional grease-resistant coating 3—an approach also emphasized in industry guides on grease-resistant paperboard for food packaging.

Recommended kraft specifications

| Kraft Type | GSM | Best Use |

|---|---|---|

| Brown kraft | 300–350 gsm | Strong retail boxes |

| White kraft | 250–300 gsm | Premium eco look |

| PE-coated kraft | 300 gsm | Oily treats |

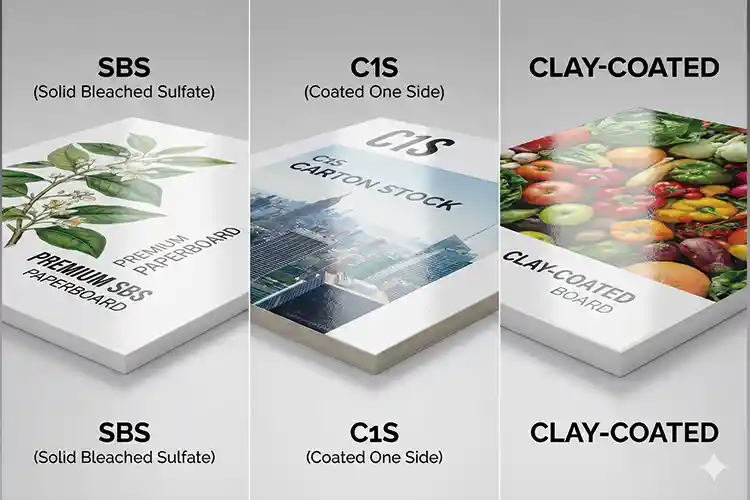

When should brands choose coated folding cartons?

Coated cartons provide smoother printing, better appearance, and improved grease resistance.

C1S and SBS cartons deliver consistent print quality and medium grease protection, following FDA food-contact compliant paperboard guidelines4.

To compare structural choices, see our

custom rigid boxes and premium-grade packaging structures.

A Japanese brand producing dry duck chips used 300gsm SBS with food-safe ink.

Their packaging kept shape even in high humidity.

PRINT & APPEARANCE QUALITY

For additional industry insight, Refine Packaging’s article on

SBS and C1S carton advantages for premium printing5

helps brands understand print consistency.

Recommended coated carton choices

| Carton | GSM | Purpose |

|---|---|---|

| SBS | 300–350 gsm | Premium look |

| C1S | 250–350 gsm | Cost-effective |

| Clay-coated | 300 gsm | Grease resistance |

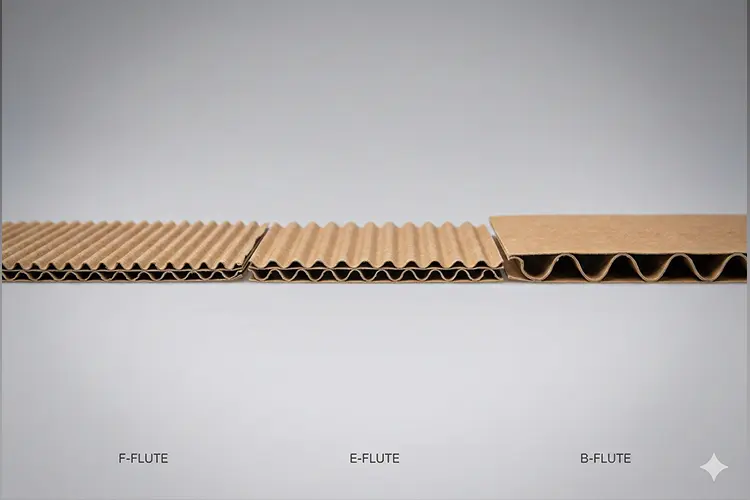

Should pet treat brands use corrugated boxes for e-commerce?

E-COMMERCE MATERIAL

E-commerce introduces compression, vibration, and long transport cycles.

Corrugated boxes excel in logistics-heavy scenarios because of

ECT & burst strength testing standards6.

A U.S. pet treat brand shipping 12-bag refill sets saw collapse in cold-weather transit using only folding cartons.

Switching to reinforced E-flute corrugated fixed the problem.

For brands evaluating mailers vs shipping boxes, PackMojo’s comparison on

corrugated mailers for subscription and e-commerce brands7

offers clear decision points.

You can also explore our

custom corrugated packaging solutions

for heavy or multi-pack shipments.

Flute options

| Flute | Strength | Best For |

|---|---|---|

| F-flute | Light | Small treats |

| E-flute | Medium | Retail mailers |

| B-flute | Strong | Bulk boxes |

Are inner pouches necessary?

INNER POUCH TYPES

Pet treats often require a second protective layer to manage oil, odor, or moisture.

Even the best PE-coated carton will eventually permeate smell or oil over long shelf life, which is why many brands follow FDA-approved food-grade pouch materials8.

To understand how inks affect flavor transfer, see our

custom print labels with low-migration ink options.

Inner liner options

| Liner | Benefit | Best For |

|---|---|---|

| PE pouch | Oil barrier | Oily treats |

| Aluminum pouch | Odor lock | Fish treats |

| Paper liner | Light barrier | Dry treats |

FAQ

Can I use 100% recycled paper for direct food contact?

No. Recycled pulp contains ink, adhesives, and mineral oils.

Studies on

mineral oil (MOSH/MOAH) contamination risk9

confirm it is unsafe for direct food contact.

If I use PE-coated paper, can I skip the pouch?

Not for long shelf life.

Coatings don’t fully block oxygen or oil migration at folded corners.

Review

oily food shelf-life recommendations10

for better planning.

Will the box make treats taste like cardboard?

Low-quality inks or uncured coatings cause this.

Industry guidelines for

low-migration inks used in food packaging11

explain how to avoid flavor transfer.

Conclusion

Pet treat packaging must balance oil content, moisture, shipping risks, and food-safe materials. By choosing the right fibers, coatings, liners, and structures—and using certified, tested materials—brands can protect product quality and avoid costly failures.

Footnotes

-

Learning standard Test Method for Rate of Grease Penetration of Flexible Barrier Materials. ↩

-

FSC standards ensure safe, clean virgin fibers for food packaging. ↩

-

Learn how coated kraft board improves grease resistance and appearance in high-oil food packaging. ↩

-

FDA rules for SBS/C1S used in treat packaging. ↩

-

Understand how SBS/C1S improve print quality and premium packaging. ↩

-

Understand how ECT and burst tests define corrugated box strength. ↩

-

Compare mailer boxes vs shippers for e-commerce use. ↩

-

Learn about FDA requirements for food-grade pouch materials. ↩

-

Scientific evidence confirming MOSH/MOAH risks in recycled pulp. ↩

-

Learn how barrier packaging extends shelf life for oily foods. ↩

-

Understand how low-migration inks prevent flavor transfer in food packaging. ↩