Did you have a misunderstanding with supplier because of incorrect measurements?

Today, i help my customer to learn from Miss Wu, she has 20 years experience in cutline and molds. Lets's see what she suggest.

Packaging cutline expert

Accurate measurements ensure proper fit your product and avoid costly mistakes. Understanding the basics makes packaging easier and more effective.

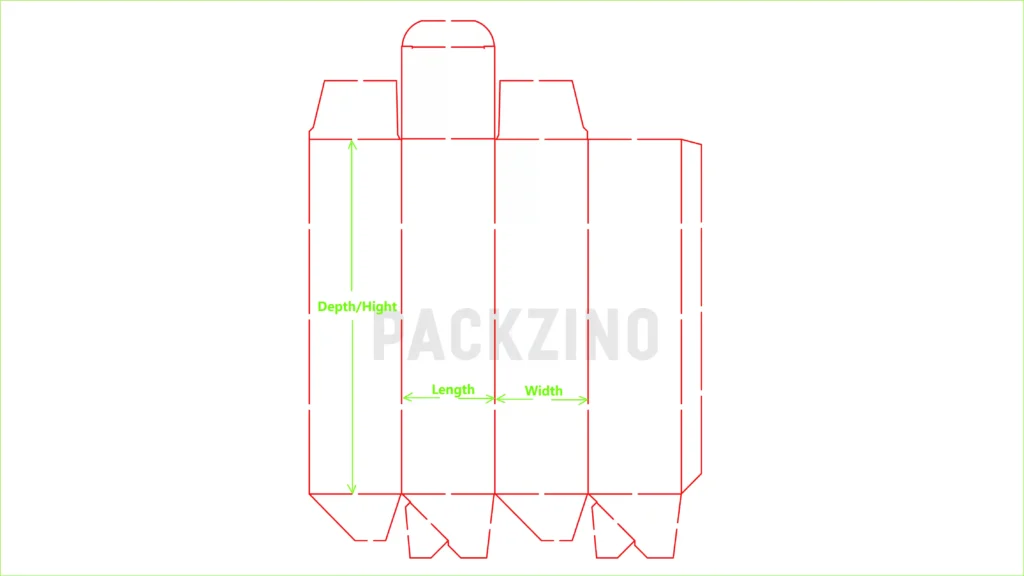

Packaging cutline

Accurately measuring a box requires attention to its length, width, and height. Each dimension plays a vital role in ensuring proper packaging fit.

Don't let incorrect measurements1 ruin your packaging plans.Let us handle the details so you can focus on what matters most: growing your business.

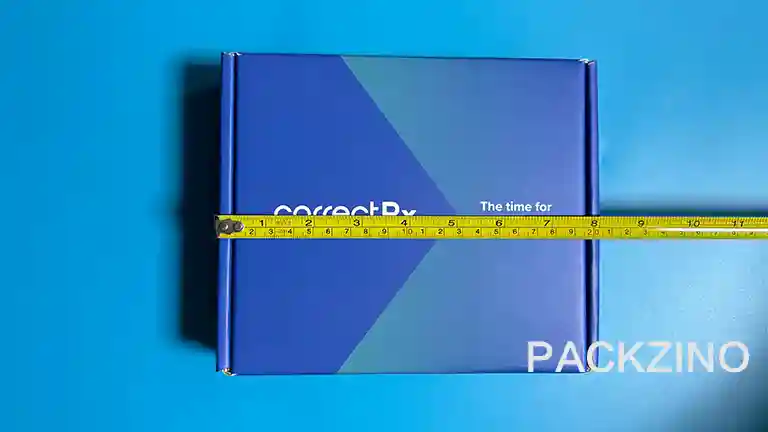

What tools are needed for precise box measurement?

Using the right tools ensures better results. Relying on basic tools like rulers often leads to errors.

For precise measurements, use tools such as measuring tapes, alipers2, and rulers designed for industrial purposes.

bottle diameter measurment

Essential tools and techniques

A simple measuring tape works for most packaging tasks, but accuracy increases with specialized tools. For instance:

- Calipers: Measure small boxes or detailed designs precisely.Ideal for achieving an accuracy of ±0.01 mm

- Laser measurers: Useful for large-scale measurements or irregularly shaped packaging.

- Rulers: Best for quick checks or prototyping.

Pros and cons of measurement tools

| Tool | Advantages | Disadvantages |

|---|---|---|

| Ruler | Affordable and easy to use | Limited to basic measurements |

| Calipers | High precision, ideal for small boxes | Expensive, may require training |

| Laser Measurer | Fast and accurate for large items | Costly, not suitable for small details |

Techniques also matter. Always measure from the inside edges for product fit, and double-check by measuring each side separately to confirm consistency. When packaging multiple items, account for any gaps between products.

folding carton measure

Imperial Units

- inches, feet: In North America (e.g., the United States, Canada) and the UK, imperial units are more commonly used.

Example: Length x Width x Height (10 x 8 x 5 inches). - millimeters, centimeters, meters: In Europe, Asia (including China and Japan), and other international markets, metric units are more frequently used

Example: Length x Width x Height (100 x 80 x 50 mm).

How do different materials affect box measurements?

Box materials can change the way you measure. Corrugated boxes, rigid boxes, and folding cartons all have unique properties.

The material's thickness3 and flexibility can alter internal and external dimensions, requiring careful adjustments.

Different thickness material

Material-specific considerations

For corrugated boxes, fluting (the wavy layer inside) adds thickness. This reduces usable internal space compared to external measurements. Always measure with this in mind. Similarly, rigid boxes are solid and retain their shape, so their external and internal dimensions remain constant.

Materials and measurement tips

| Material | Key Consideration | Adjustment Tips |

|---|---|---|

| Corrugated | Fluting adds thickness | Deduct thickness from internal space |

| Rigid | Uniform shape, no compression | Internal and external dimensions match |

| Cartons | Lightweight, prone to bending | Measure carefully for accurate fit |

Packaging for heavy items requires stronger materials, which may alter box proportions. For lightweight items, thinner materials work but may need extra space for cushioning.

What are the common mistakes in measuring boxes?

Mistakes in measurements can lead to problems like fitting issues, wasted materials, or increased costs.

Common errors include measuring only external dimensions, neglecting material thickness, and using imprecise tools.

measure the size exterior-wrong

Avoiding measurement pitfalls

To avoid mistakes:

- Know your purpose: Are you measuring for shipping, stacking, or product fit? Each requires a different focus.

- Account for tolerances: Allow for slight variations, especially for corrugated materials.

- Use the right tools: As mentioned earlier, tools matter. A quick measurement with a ruler might suffice for prototypes, but precision tools are better for final designs.

Mistakes and solutions

| Mistake | Why It Happens | Solution |

|---|---|---|

| Measuring externally only | Overlooking material thickness | Always measure internal dimensions too |

| Ignoring tolerances | Assuming exact measurements work | Add small margins to account for error |

| Using improper tools | Lack of specialized equipment | Invest in industrial-grade tools |

Reviewing your measurements twice saves time. It ensures your products will fit perfectly and avoid waste.

Why is it important to measure a box accurately?

Accurate box measurements save money and reduce waste. Improper sizes can lead to damaged goods or excessive costs in materials and shipping.

Measuring a box ensures that products fit securely, preventing damage during shipping and avoiding unnecessary material waste.

5ml bottle width measurement

The basics of box measurement

Box measurement starts with identifying its dimensions: length, width, and height. These terms often confuse buyers. The length is the longest side of the box opening. The width is the shorter side of the opening. The height (or depth) is the distance from the base to the top.

Key dimensions and their definitions

| Dimension | Definition | Common Applications |

|---|---|---|

| Length | Longest side of the box opening | Determining product fit |

| Width | Shorter side of the box opening | Balancing aesthetics and space usage |

| Height | Distance from base to the top | Ensuring proper stacking and storage |

Measuring internally versus externally also matters. Internal measurements reflect usable space, while external dimensions include the box’s thickness. Both are important depending on your goal. Internal dimensions are critical for product fit, while external measurements are used for shipping and stacking.

Conclusion

Accurate box measurement involves understanding dimensions, using proper tools, and adjusting for materials. Avoid mistakes by double-checking and using suitable methods for each packaging type.

Get it right the first time with PACKZINO—where precision meets creativity. Let us handle the details so you can focus on what matters most: growing your business.

-

Learn about the potential pitfalls of incorrect measurements and how to avoid them to save time and resources. ↩

-

Explore the benefits of using calipers for precise measurements, including versatility and accuracy in tight spaces. ↩

-

Understand how packaging material properties influence dimension measurements and why this matters in box design and production. ↩