Candy boxes usually fail in two ways. The paper gets ugly oil stains, or the box collapses during shipping. I solve these problems by choosing the right food-contact surfaces and the right physical structure.

Food-grade packaging is not just about a paper certificate. Every part of the box—the board, the coating, the ink, and the glue—must be safe for food contact 1. These materials must also stay strong and clean under the heat and pressure of shipping.

Below is my breakdown of paper types, barriers, and window materials. I also include the specific details I check before we start production.

What does “food-grade paper” really mean for candy boxes?

You should not treat "food-grade" as a marketing buzzword. If you do, you will face customer complaints. In my factory, I treat it as a technical requirement.

Food-grade is a complete system. The paper, coating, ink, and glue must work together. They must match the candy type and the laws of the country where you sell your product.

FOOD CONTACT SYSTEM

I learned this the hard way with an order of sugar-coated gummies. The buyer bought expensive food-grade paper. However, they used cheap glue for the window to save money. The boxes were packed into large cartons before the glue was fully dry. The fumes stayed trapped inside. By the time customers opened the boxes, the gummies tasted like chemicals. We had to recall the entire shipment. Now, I always check the "full system" including the glue and the drying time.

What I check first on a candy box project

I always look at how the candy touches the paper. Many boxes use an inner bag. However, grease and smells can still move through the materials.

| Question I ask | Why it matters | My typical decision |

|---|---|---|

| Is there an inner bag? | Direct vs. indirect contact | No bag? I use a high-performance barrier |

| Is the candy oily? | Oil leaks through paper fibers | I avoid porous or uncoated paper |

| Is the environment hot? | Heat makes oil leak faster | I choose heat-resistant coatings |

| Retail shelf or Mailer? | Crush vs. Appearance | For shipping, I use thicker paper |

Which paper types fit different candy products without causing stains or crush?

Do not pick paper based on "look" alone. If you do, you risk oil stains and weak corners. You must pick paper based on how the candy behaves inside the box.

The best paper for a candy box depends on oil content and shipping pressure, not just print quality.

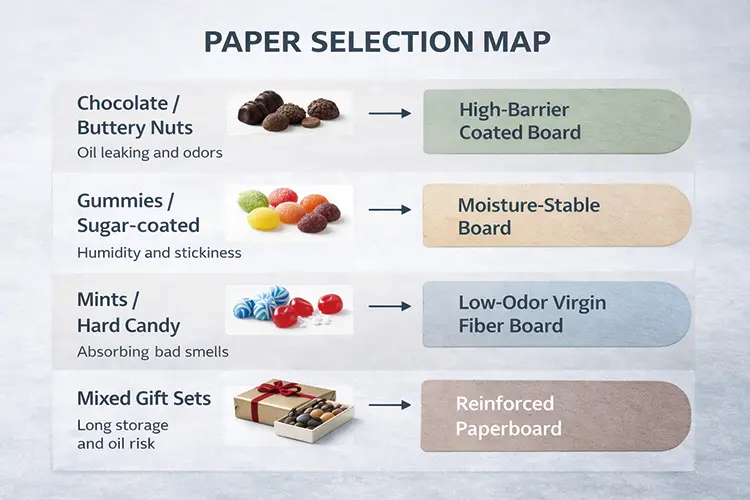

PAPER SELECTION MAP

I once saw a brand use beautiful artisan paper for chocolate truffles. On day one, it looked great. By day ten, the butter from the chocolate leaked into the paper fibers. It left dark, greasy rings on the bottom of the box. The fix was not thicker paper. We had to switch to grease-resistant (GR) board.

For more real-life print and packaging issues, see how other suppliers prevent packaging test failures and shipping damage 2.This board has a barrier that blocks oil at a molecular level.

Step 1: Match candy type to paper risk

| Candy type | Main packaging risk | Paper direction |

|---|---|---|

| Chocolate / Buttery nuts | Oil leaking and odors | Use high-barrier coated surfaces |

| Gummies / Sugar-coated | Humidity and stickiness | Use moisture-stable boards |

| Mints / Hard candy | Absorbing bad smells | Use low-odor virgin fiber paper |

| Mixed Gift Sets | Long storage and oil risk | Use a reinforced structure |

Step 2: Choose a board family

I always tell my clients: "Candy is heavy." If you use thin paper to save money, the bottom boxes will burst at the corners. I design the folds to carry the weight. This prevents the flat panels from buckling under the product weight.

How do I choose coatings and barriers that stay clear, safe, and easy to ship?

If you pick the wrong barrier, the box fails after two weeks. A good barrier keeps the oil inside the candy. It also keeps the window clear.

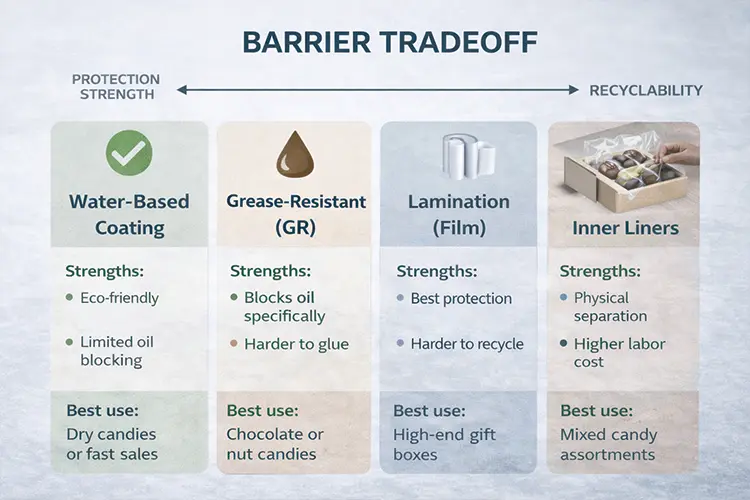

BARRIER TRADEOFF

Many buyers blame the window film when it looks "cloudy." In my experience, the problem is often trapped moisture or oil vapor. We had a client whose windows fogged up during summer shipping. The vapor could not escape the sealed box, so it turned into mist on the plastic. We solved this by using a "low-fog" film. We also adjusted the glue pattern to allow a tiny amount of air to move through the corners.

What I mean by “barrier” in a candy box

| Barrier approach | Strength | Weak point | Best use |

|---|---|---|---|

| Water-based coating | Eco-friendly | Limited oil blocking | Dry candies or fast sales |

| Grease-resistant (GR) | Blocks oil specifically | Harder to glue | Chocolate or nut candies |

| Lamination (Film) | Best protection | Harder to recycle | High-end gift boxes |

| Inner Liners | Physical separation | Higher labor cost | Mixed candy assortments |

Which window patch materials reduce heat warping, scratching, and buyer complaints?

Do not choose a window just because it is clear. It might warp or scratch before it reaches the customer. I treat windows as "weak points" that need careful engineering.

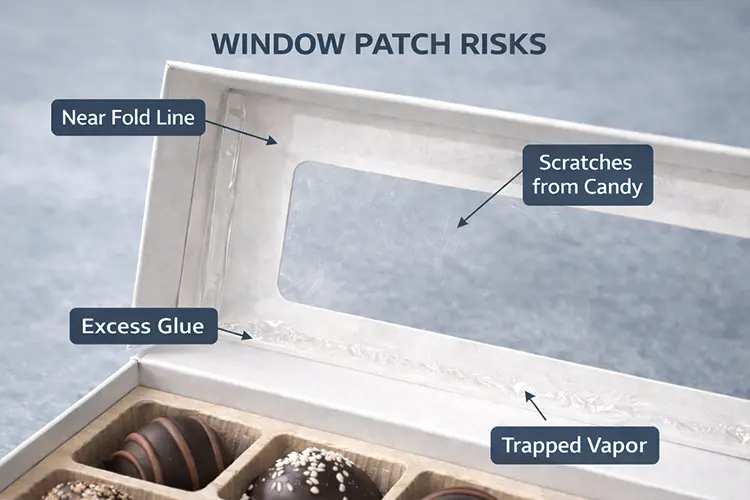

WINDOW PATCH RISKS

Design details that prevent failure

- Stay away from folds: If the film is too close to a fold line, the tension makes the box bend. It also makes the film wrinkle.

- Control the glue: Too much glue causes "hazing" or cloudiness. We use the exact amount of glue to keep it clean.

- Prevent scratches: If the candy is heavy, it will rub against the window during shipping. I often use a "treated" PET film to prevent this damage.

Frequently Asked Questions (FAQ)

1. Is all food-grade paper grease-proof?

No. Food-grade paper is safe for contact, but it can still absorb oil. You must specify a Grease-Resistant (GR) coating 3 or a Kit-rated board (level 1–12) 3 to stop oil stains.

2. Why do candy box windows get foggy?

This is called "outgassing." Heat makes the candy oils or the window glue evaporate. This gas turns into mist inside the box. Use anti-fog PET film 4 and low-VOC adhesives 4 to keep windows clear.

3. What paper weight (GSM) should I use?

Standard boxes use 300gsm to 350gsm. If you ship via e-commerce, I recommend at least 400gsm. You can also use E-flute corrugated board to prevent crushing.

4. Can I recycle candy boxes with windows?

Boxes with water-based coatings are easy to recycle. However, you must usually remove plastic windows first. For 100% recyclability, ask for cellulose-based films and plastic-free coatings.

5. How do I prove my box is food-safe?

Ask your manufacturer for a Declaration of Compliance (DoC) [^5]. This document covers the paper, ink, and glue. It proves that no chemicals will move from the box into your candy.

Conclusion

A great candy box is a complete system. It must protect your product from oil stains, humidity, and shipping damage. If you choose the right materials today, you avoid expensive recalls tomorrow.

Would you like me to suggest a specific paper weight (gsm) or barrier for your candy type?

-

Understand official definitions and regulations for safe food contact packaging materials. ↩

-

Learn common packaging test failures, why boxes crush or fail in transit, and how to prevent these issues. ↩

-

Learn how grease resistance is tested and what Kit numbers mean for food packaging. ↩ ↩

-

Learn how anti-fog films and low-VOC adhesives keep carton windows clear in hot, humid shipping conditions.

[^5]: Understand what a Declaration of Compliance must contain and how to issue it for food-contact packaging. ↩ ↩