Glass candles sell emotion and luxury. But in the world of shipping, glass is a liability. I see many brands spend thousands on fragrance and wax. Then, they lose money because their jars crack in transit. Most failures do not come from the glass. They come from a weak box structure.

DAMAGED VS PROTECTED GLASS CANDLES

I write this from my experience on the factory floor, where my team and I work daily on custom candle packaging for glass products shipped worldwide.

I look at packaging after it leaves the designer's desk. I see what happens in trucks and messy warehouses. My goal is simple. Your candles must arrive in one piece.

Why Do Glass Candle Jars Break Inside Boxes During Shipping?

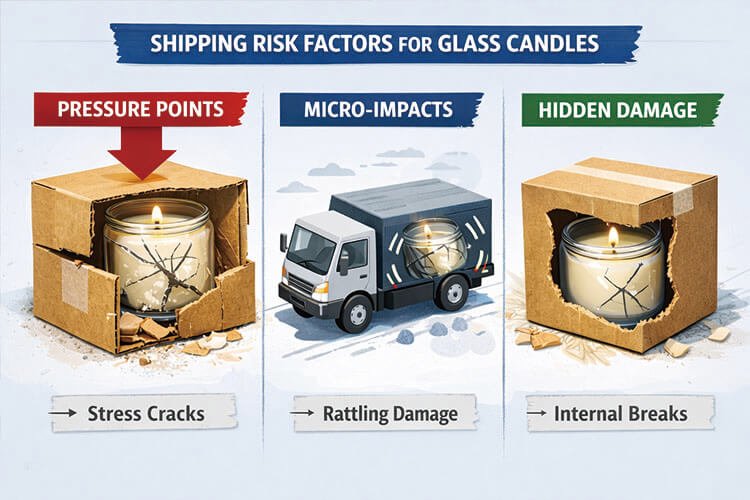

SHIPPING RISK FACTORS FOR GLASS CANDLES

Glass jars do not just break from a single drop. Most damage happens slowly. It comes from repeated stress during the journey.

Glass weight and the "Pressure Point"

Glass candles are bottom-heavy. When you stack these boxes, the weight sits on one small area. If the box walls are thin, they will flex. The force then moves inward. It presses directly onto the glass jar.

I often see boxes that look perfect on the outside. But inside, the jar is already under too much pressure. The glass develops small "stress cracks." These cracks grow during the trip. The customer only sees the damage when they open the box.

The danger of "Micro-Impacts"

Shipping trucks vibrate every second they are on the road. If your jar can move even 2 mm, it is in danger. The jar will hit the insert walls thousands of times. Each hit is small, but they add up as micro‑impacts during vibration testing 1.

This is why loose inserts are a factory's nightmare. They allow movement. Even if the driver is careful, vibration alone can chip the rim of your expensive glass.

Why hidden damage happens

Many brands only worry when the outer carton looks crushed. That is a mistake. Packaging often fails from the inside out. The box absorbs the hit but passes the energy to the glass. From my view, the structure failed before the truck even left the dock.

Factory Case Study:

We once had a client using standard folding cartons for a heavy 16oz glass jar. The boxes looked great, but they had a 15% breakage rate. We did a pallet test in the warehouse. We found that the bottom row of cartons was compressing by 3 mm of carton compression 2. This 3 mm of movement was enough to snap the glass seals. We switched them to a 1400gsm rigid box, and the breakage dropped to near zero.

Rigid Boxes vs Folding Cartons — How Structure Handles Glass Weight

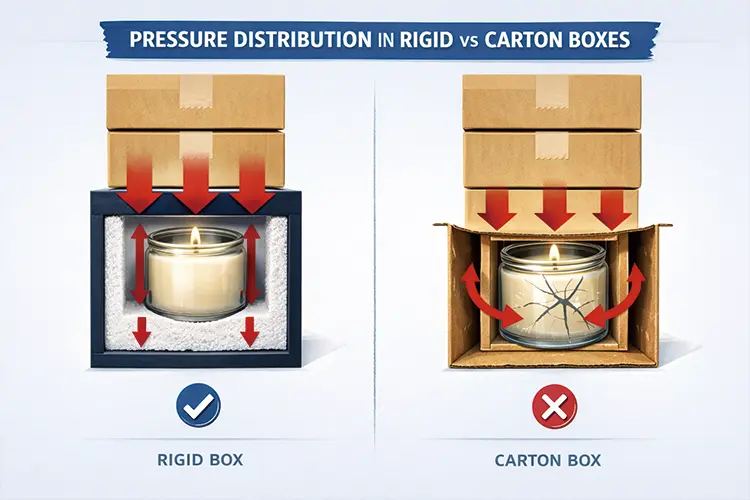

PRESSURE DISTRIBUTION IN RIGID VS CARTON BOXES

Rigid boxes and folding cartons are not just different styles. They are different tools.

For glass candles, the right tool depends on jar weight, route, and how you ship — all of which are covered in this complete guide to candle shipping boxes 3.

How rigid boxes carry the load

A rigid box uses thick board and fixed corners. The walls do not bend. When you stack these boxes, the weight travels through the corners. The box carries the load. The candle stays safe in a protective cage. I check every corner during production. Strong corners keep the box square and the product isolated.

Why folding cartons have limits

Folding cartons are cheap and save space. But their fold lines are weak points. Under heavy pressure, the walls will flex inward. The force has nowhere to go. It pushes straight into your candle.

| Factor | Rigid Box | Folding Carton |

|---|---|---|

| Load path | Through walls and corners | Directly to the glass |

| Shape stability | Stays square | Flexes under weight |

| Stack resistance | Excellent | Limited |

| Risk for heavy glass | Very low | High |

When Is a Folding Carton Enough — And When Do You Need a Rigid Box?

REAL-WORLD SHIPPING CONDITIONS FOR GLASS CANDLES

This is what my clients ask me most. There is no perfect box. There is only the right box for your risk.

When cartons work

Based on common freight stacking limits and standard pallet loading conditions, cartons can work for small, light jars under 200 g that ship locally. In these cases, a strong carton combined with a precise insert is often enough to stop movement and prevent damage.

When you must use a rigid box

In most commercial fulfillment environments, once a glass jar exceeds 400 g, a rigid box becomes the safer standard. This is especially true for long-distance shipping or platforms like Amazon FBA, where cartons are stacked high and handled fast.

The "Hidden Cost" Lesson:

I worked with a brand that chose cartons to save $0.50 per unit.They ignored the cost of returns. After one month, they were losing $2,000 a week in broken jars and shipping fees for replacements — a classic example of why you need cost‑effective candle packaging for shipping 4. We helped them move to a rigid box. The unit price went up, but their total loss disappeared.

How Inserts, EVA, and Box Finishes Work Together

BENEFITS OF PROPER GLASS CANDLE PACKAGING

A good box is a system. Every part must do its job.

Inserts lock the position

I use calipers to measure every jar. If the insert is even 2 mm too big, the candle is at risk. For heavy glass, I avoid thin paper inserts. They lose their shape after a few days in a humid warehouse.

EVA foam is the best insurance

EVA foam inserts 5 absorb shock. They compress and rebound. For premium candles, I often recommend EVA because it handles drops and vibration that paper inserts cannot control.

Finishes come last

Foil and texture are for the customer's eyes. They matter, but they do not protect the glass. A broken candle in a beautiful box is still a broken candle.

| Component | Function | The risk |

|---|---|---|

| Insert | Locks the jar | Internal hits |

| EVA | Absorbs shock | Cracks on impact |

| Finish | Brand look | Loss of trust |

FAQ

1. Is a rigid box always the safest choice for glass candles?

Yes, in high-risk shipping conditions. A rigid box offers the best protection against stacking pressure and corner damage. For jars over 400 g or long-distance shipping, it is the safer standard.

2. Why do my glass jars break even if the outer box looks fine?

This happens because of static load. The weight of other boxes causes the walls to flex inward. The box may recover its shape, but the glass inside stays cracked.

3. Does EVA foam really protect better than paper inserts?

Yes. Paper inserts provide structure but little shock absorption. EVA stays resilient and absorbs micro-vibrations from delivery trucks.

4. How can I tell if my folding carton is strong enough?

Try a thumb test. Press firmly on the center of the wall. If it flexes more than 3 mm, it will likely fail under pallet stacking.

5. Will premium packaging help reduce my Amazon return rate?

Yes. Most candle returns come from damage on arrival. A rigid structure and precision‑fit inserts remove the main cause of these returns.

Conclusion

Packaging for glass candles is about managing force. You must lock the jar in place and carry the weight of the pallet. When structure and inserts work together, your brand stays safe from our factory to your customer's home.

-

Learn how standardized vibration and drop tests reveal micro‑damage risks in fragile glass packaging. ↩

-

See how carton compression strength and small deformations translate into stacking failures. ↩

-

Get a full checklist for designing candle shipping boxes, from sizing to inserts and cushioning. ↩

-

See practical ways to balance candle packaging cost with protection for nationwide shipping. ↩

-

Learn how EVA foam compares to other foams for shock absorption, vibration control, and protection. ↩