I often see chocolate brands spend a fortune on premium ingredients. Then, they lose everything during shipping. The chocolate cracks. The surface turns dull and white. Customers complain immediately. Most of these issues start with the packaging box, not the chocolate itself.

Luxury chocolate box design must do more than look pretty. It must fight heat, pressure, and vibration. Your inserts, rigid structures, and surface finishes must work together to stop damage before it happens.

I speak from 16 years of factory experience. Our boxes for messy shipping and hot warehouses, not just for Instagram photos.

Why do luxury chocolate gift boxes fail during shipping and storage?

SHIPPING RISK FACTORS

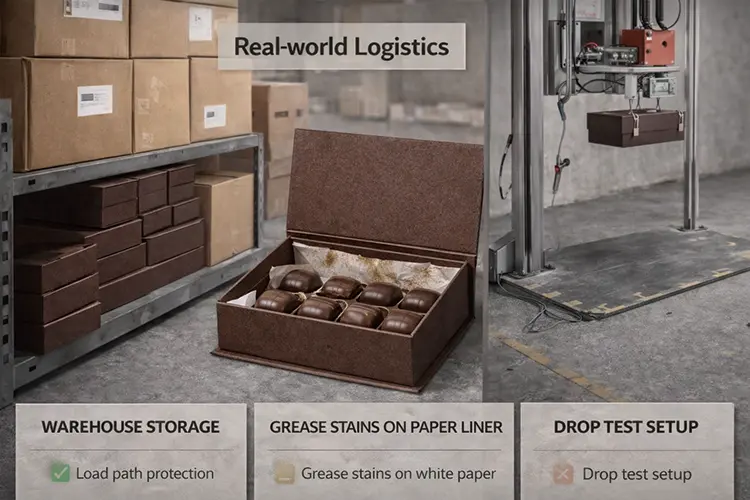

Most boxes look perfect when they leave my factory. They fail later. Real-world logistics create risks that a designer might ignore in a clean office.

Heat exposure in real logistics

Chocolate reacts to heat instantly. It does not need to melt to be ruined. First, the glossy surface turns dull. Then, the corners soften. I see this happen in last-mile delivery vans every summer. Dark-colored boxes are a risk. They soak up heat and hold it. This creates a "mini‑oven" effect 1 inside your packaging.

Internal movement during transport

Many brands use loose inserts to save money. This is a mistake. During transport, the truck vibrates constantly. The chocolates hit the insert walls thousands of times. Even if the box looks fine outside, the chocolate inside will have tiny cracks and chips when the customer opens it.

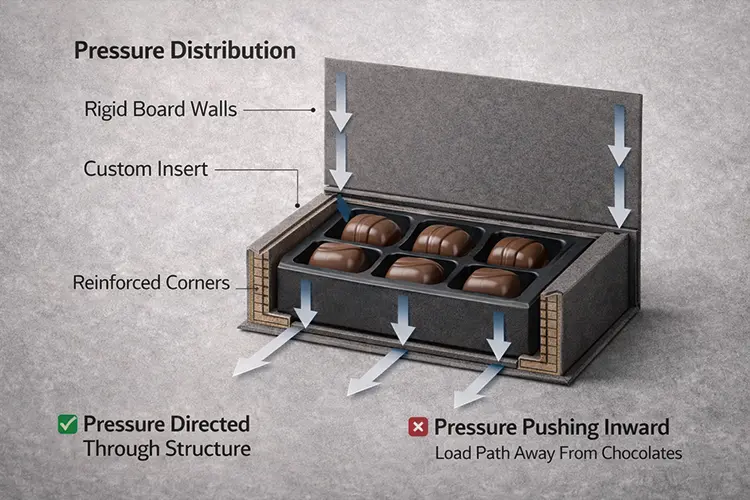

Stacking pressure and load transfer

If your rigid box walls are thin, the pressure moves inward, unlike well‑engineered rigid chocolate gift boxes that carry the load through their structure. It pushes directly onto the chocolate. I have opened boxes with no damage outside and found crushed chocolates inside because the force transferred straight through the walls.

| Risk Factor | What Happens | Common Result |

|---|---|---|

| Heat | Surface oil migrates | Dull grey bloom |

| Vibration | Constant small hits | Chipped edges |

| Pressure | Heavy weight on top | Crushed shapes |

Last Christmas, a high-end chocolatier sent 5,000 boxes to a fulfillment center. They used a beautiful 1200gsm box, but the inner paper grid was too thin (only 200gsm). When the shipping cartons were stacked five high, the bottom boxes flexed. The grids collapsed, and the chocolates smashed into each other. We fixed this for their next run by upgrading to a 400gsm reinforced interlocking grid.

How do custom inserts prevent chocolate cracking and deformation?

INSERT PRECISION AND PROTECTION

I treat inserts as insurance policies. They must lock the product in place to stop movement.

Why precision fit matters

I never guess the size of a chocolate. I use digital calipers to measure every SKU. If a gap is even 2 mm wide, the chocolate will rattle. I design my inserts with a 0.5 mm tolerance. This creates a "snug fit." When the movement stops, the damage stops.

Insert material behavior under stress

Different materials handle vibration differently. I choose material based on your shipping journey and your brand goals.

| Insert Type | Movement Control | Shock Protection | Visual Level |

|---|---|---|---|

| Paper Grid | Good | Low | Classic |

| Molded Pulp | Great | Medium | Eco-Friendly |

| PET Tray | Excellent | Low | Clean |

| EVA / Flocked | Maximum | High | High-End |

I often suggest 350gsm paper for grids. If you use thin paper, it will fold under stress, especially without grease‑resistant food packaging paper 2 to block cocoa butter.For very expensive truffles, I recommend EVA foam. It costs more, but it absorbs every bump on the road.

Orientation and real shipping conditions

Boxes travel flat, upright, and tilted. Some inserts work well flat but fail when a delivery driver stands the box on its side. I test inserts in every position. If the chocolate slides or leans, the design is not ready for production.

How does rigid box structure help control pressure and temperature?

RIGID STRUCTURE STRENGTH

A strong box is your first line of defense. It must carry the weight so your chocolate doesn't have to.

Pressure distribution inside rigid boxes

A strong box carries the load through its corners. I focus on "corner integrity." If the corners stay square under pressure, the box won't cave in. Weak boxes bend inward and crush your inserts.

Board thickness versus box size

Thickness helps, but you must match it to the box size. Larger boxes need much stronger walls to resist the weight of other cartons.

| Box Size | Recommended Board | Purpose |

|---|---|---|

| Small (4-6 pcs) | 1200 gsm | Keeps the shape |

| Medium (12-24 pcs) | 1400 gsm | Resists stacking |

| Large (30+ pcs) | 1800 gsm | Heavy load control |

Temperature buffering effect of paperboard

Paperboard does not cool chocolate, but it acts as an insulator. It slows down temperature changes. This delay is critical during the last mile of delivery. Thin boxes change temperature too fast and increase your risk of fat bloom on chocolate 3.

How do brands design luxury chocolate boxes for real shipping conditions?

DESIGN FOR REAL-WORLD LOGISTICS

Successful brands design from the truck backward. They don't start with the look; they start with the journey.

Balancing luxury with food safety

Chocolate absorbs surrounding odors 4. If your factory uses cheap glue or solvent-based inks, the chocolate will taste like chemicals. I only use low-odor, food-grade glues and soy-based inks. I also use grease-resistant liners to stop oil from soaking into the paper and creating ugly stains.

One client was losing 10% of their stock because their "organic" paper inserts were absorbing cocoa butter. The boxes looked dirty and old. We switched them to a grease-proof food-grade paper 5 with a hidden PE coating. The stains vanished, and their shelf-life doubled.

Shipping efficiency and structure choice

Oversized boxes cost more to ship. I reduce the outer dimensions while keeping the inner protection thick. This saves you money on every air freight shipment.

Flexibility for seasonal and small-batch brands

Many brands launch seasonal flavors. I design modular structures. You can keep the outer box standard and only change the cheap inner insert. This keeps your costs low while maintaining high quality.

FAQ

1. Does foil stamping increase heat risk for chocolate packaging? Foil stamping itself does not create heat, but large areas of dark-colored foil can accelerate heat absorption. Dark metallic surfaces trap thermal energy faster than light-colored paper when exposed to direct sunlight or warm delivery vans. To minimize risk, I recommend using localized foil accents rather than large, solid metallic blocks on the outer box.

2. Why does chocolate pick up a "chemical" or "paper" taste from the box? Chocolate absorbs surrounding odors because its high fat content acts as a natural sponge for volatile organic compounds (VOCs). If your packaging uses standard industrial glues or solvent-based inks, the chocolate will inhale these chemical scents through the paper layers. Always specify food-grade soy inks and low-odor, water-based adhesives to preserve the original flavor profile.

3. What is the best insert material to prevent chocolate cracking during shipping? Custom-molded PET trays and high-density EVA foam provide the best protection against chocolate cracking. These materials create a precision "lock" that stops the product from rattling during high-frequency vibrations in air or truck freight. For a more sustainable luxury option, I suggest a heavy-weight (350gsm+) interlocking paper grid with a 0.5 mm fit tolerance.

4. Are magnets safe to use in luxury chocolate gift box lids? Magnets are safe for chocolate packaging as long as they are fully encased within the rigid board and do not come into direct contact with the food. While magnets provide a premium closing experience, the magnetic pull must be calibrated; a closure that is too aggressive can shake the delicate chocolates every time the lid snaps shut, leading to surface chipping.

5. How do you prevent oil stains or "grease bloom" on chocolate box inserts? To prevent oil stains, you must use grease-resistant liners or food-grade aqueous (AQ) coatings on all paper inserts. Chocolate fats naturally migrate over time, and without a functional barrier, these oils will soak into the paper fibers, creating unsightly dark spots. A glassine paper overlay is also an effective, traditional way to create a temperature and oil buffer.

Conclusion

Benefits of Proper Packaging

Luxury chocolate packaging is about control. You must control the movement, the pressure, and the temperature. When you get the structure right, your brand stays premium from our factory to the customer's door.

-

Understand how heat and temperature swings cause chocolate bloom and surface dullness. ↩

-

Learn which food-grade papers stop chocolate fats from soaking and staining your inserts. ↩

-

Dive into scientific research on how temperature swings create fat bloom on chocolate surfaces. ↩

-

See why chocolate absorbs nearby odors and how proper packaging and storage prevent off-flavors. ↩

-

See how glassine and grease‑resistant papers protect chocolates from oil stains and damage. ↩