Cake boxes look simple, but incorrect sizing can quickly lead to crushed edges, leaning layers, and delivery failures that turn into refunds.

Factory experience shows that choosing the right cake box is not just about matching the diameter; it requires understanding the cake’s internal stability, the board’s pressure tolerance, and the delivery conditions. Weight, height, and moisture levels must all work together to prevent structural failure.

What Factors Determine the Correct Cake Box Size?

The correct cake box size depends on four key factors: cake height, total weight, moisture level 1, and the delivery method used.

Most sliding, oil seepage, and delivery issues trace back to incorrect judgments about a cake’s dimensions, weight, and environmental exposure.

SIZE FACTORS

Factory Case Study (Moisture Risk)

A client specializing in high-moisture Mango Mousse Cakes used a standard 300 GSM box. Under humid bakery conditions, the paper fibers softened, causing the box to tilt and lose rigidity. Upgrading to 350 GSM Duplex Board with PE Lamination 2 stabilized the structure and eliminated seepage within days.

Key Pre-Selection Factors

- Height Buffer: Vertical clearance 3 prevents frosting from touching the lid.

- Weight Load: Determines whether the base can handle lifting and transport stress.

- Moisture Resistance: High-moisture cakes require paper that maintains rigidity in humid or refrigerated environments.

- Delivery Style: Motorbike or high-frequency delivery requires tighter internal fit and stabilization inserts.

- Grease Barrier: Materials must resist oil penetration to maintain appearance.

- Cake Type: Each category—chiffon, mousse, mille crepe, and other dessert & sweets packaging—places different demands on rigidity and side-wall strength.

Cake Box Size and Structure Matching Guide

| Factor | Why It Matters (Factory View) | Recommended Action |

|---|---|---|

| Height | Prevents contact with frosting and top décor. | Add 1 to 1.5 inches of clearance. |

| Weight | Ensures the base doesn't deform under load. | Use Lock-Bottom or Double-Wall for heavier cakes. |

| Moisture | Prevents softened walls and collapse. | Choose PE/PP coated or laminated food-grade board. |

| Movement | Limits lateral shifting during delivery. | Use a Cake Insert or reduce internal width. |

What Happens When Your Cake Box Size Is Incorrect?

Incorrect cake box sizing leads to slower packing, higher delivery failure rates, and increased customer complaints due to smearing or collapse.

Incorrect sizing creates a chain reaction inside the bakery: slower packing, unnecessary returns, and unpredictable workflow.

SIZE IMPACT

We worked with a US chain that relied on only two box sizes. The mismatch caused repeated adjustments during packing, adding about 5 seconds per order. Across 300 daily orders, this resulted in a 15% slowdown. By expanding the size range and adopting an Auto-Bottom design 4, packing time stabilized immediately.

Size Optimization's Impact on Operations

- Packing Speed: Correct sizing enables fast, predictable packing with minimal staff adjustment for bakery and cake packaging.

- Complaint Reduction: Proper height and width reduce smearing, crushing, and customer complaints after delivery.

- Stability: A properly matched box significantly reduces internal shifting during transit.

- Brand Consistency: Smooth-opening gift and brand packaging boxes reinforce a professional customer experience.

Common Size Problems & Factory Solutions

| Packaging Problem | Root Cause | Expert Factory Solution |

|---|---|---|

| Frosting Smears on Lid | Insufficient headroom. | Increase height by 1.5 inches. |

| Cake Slides Inside Box | Internal width too loose. | Tighten width or add an insert. |

| Leaning Layers / Sagging Base | Insufficient bottom strength. | Upgrade to Lock-Bottom or E-Flute base. |

| Grease Stains | Uncoated or thin stock. | Use Coated SBS or apply PE/PP Lamination. |

How Do You Choose the Right Cake Box Size for Each Cake Type?

Choosing the right cake box size starts with matching the cake’s diameter and height, then adjusting for its structure, weight, and moisture level.

Standard cake box sizes 5 help, but ideal fit requires fine adjustments based on cake structure, height, and weight.

STANDARD SIZES 4INCH, 6INCH

Standard Cake Box Sizes & Factory Height Recommendations

| Cake Size | Cake Diameter | Suggested Box Size | Factory Recommended Height |

|---|---|---|---|

| 4-inch | 10 cm | 4 x 4 in | 4.5 inches |

| 6-inch | 15 cm | 6 x 6 in | 5.5 inches for lighter/shorter cake profiles |

| 8-inch | 20 cm | 8 x 8 in | 6.5 inches for taller cream layers |

| 10-inch | 25 cm | 10 x 10 in | 7.5 inches for large celebration cakes |

Structural and Sizing Customization

- Chiffon Cake: Tall and airy — requires generous vertical clearance.

- Mousse Cake: High moisture — board selection directly impacts structural rigidity.

- Mille Crepe: Dense and layered — requires a reinforced base that distributes downward pressure.

- Cheesecake: Heavy — load-bearing reliability becomes the top priority.

What Box Structures Prevent Cakes From Collapsing During Delivery?

Lock-bottom, double-wall, and reinforced bases 6 prevent cake collapse by distributing weight and resisting lateral pressure during delivery.

Structure defines load capacity. Most failures occur when the box cannot withstand combined stress from weight, moisture exposure, and transport handling.

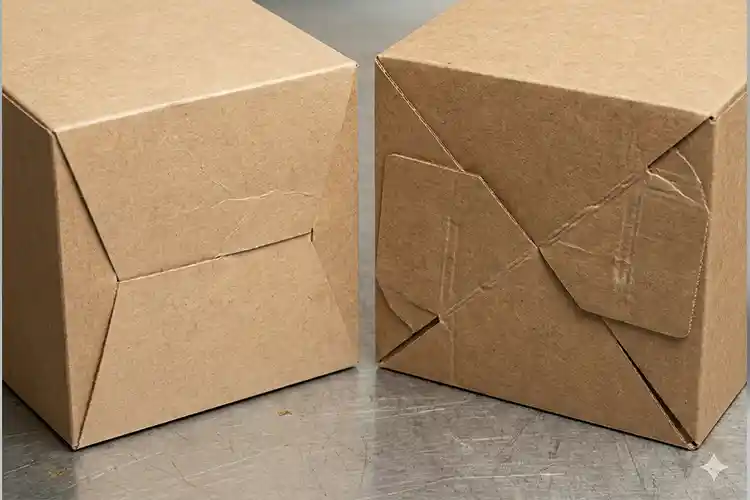

Lock-Bottom vs Auto-Bottom Cake Box Base Structure

Factory Case Study (Structural Failure)

A client’s 8-inch birthday cake used a thin-wall structure that warped slightly when lifted, causing the cake to slide. Switching to 400 GSM Duplex Board and a strengthened Lock-Bottom base eliminated the issue and improved handling stability.

Key Anti-Collapse Structure Types

- Auto-Bottom: Fastest assembly; ideal for moderate-weight products.

- Lock-Bottom (Manual): Interlocking flaps distribute pressure across multiple points, offering top-tier stability.

- Double-Wall: Adds side-wall thickness for resistance against squeezing or tall-product instability.

- Window Patch: Requires durable PET film and strong adhesive to maintain rigidity.

Cake Box Structure Comparison & Factory Advice

| Structure | Strength Rating | Best For | Factory Experience Notes |

|---|---|---|---|

| Auto-Bottom (Glued) | Medium-High | Cakes under 1.5 lbs | Prioritizes speed; requires moisture-resistant adhesives. |

| Lock-Bottom (Manual) | Highest | Heavy cakes (Cheesecakes, Tarts) | Most stable option for demanding delivery conditions. |

| Double-Wall | Very High | Tall cakes (>7 inches) | Essential for protecting sidewalls from collapse. |

| Window Patch | Variable | Retail / Display | Needs 0.05mm+ PET film for reliable structure. |

FAQ: Common Questions About Selecting the Right Cake Box Size

1. How much height clearance should a cake box have?

Most cakes need 1 to 1.5 inches of additional height to prevent frosting from touching the lid. Tall chiffon or multi-layer cakes may require up to 2 inches depending on decoration.

2. What is the strongest box structure for heavy cakes?

Dense cakes such as cheesecakes or mille crepe perform best in a Lock-Bottom base, which offers the highest load-bearing strength. Adding a double-wall side panel further increases structural stability.

3. How do I prevent cakes from sliding inside the box?

Sliding usually occurs when the internal width is too loose. A tighter box size or a custom-fit cake insert will secure the cake and prevent lateral movement.

4. Which paper material is best for moist or refrigerated cakes?

Moisture-sensitive cakes require PE- or PP-laminated Duplex Board, which maintains rigidity under humidity and refrigeration, preventing soft walls and collapse.

5. How do I choose the right size for delivery services like motorbikes?

Motorbike delivery demands compact, stable coffee-to-go packaging. Choose a box with minimal internal gaps, reinforce the base, and use inserts to limit movement during transport.

Factory production

The Formula for Stable and Efficient Bakery Packaging

The right cake box size and structure 7 form the foundation of stable, predictable, and cost-efficient bakery operations.

Your Next Step: If you need advice on whether your signature products require Lock-Bottom strength, or if you want to incre

-

Learn how moisture and grease affect cake box strength and food safety. ↩

-

Explore food-safe cake box materials and coatings for moist or chilled cakes. ↩

-

Learn step-by-step how to measure cake box length, width, and height correctly. ↩

-

See what auto-bottom boxes look like and why they speed up packing. ↩

-

Compare your cake sizes with a detailed box dimension chart for common formats. ↩

-

Discover real-world custom cake box options using strong, delivery-ready structures. ↩

-

See how packaging choices impact bakery product quality, safety, and shelf life. ↩