Over the last 5 years at Packzino, I've seen countless brilliant skincare formulas fail not because of the product, but because the packaging couldn't survive the courier truck.

The best material isn't about "luxury" vs "cheap"—it's about physics. A heavy 50g glass cream jar needs at least 350gsm paper to avoid that ugly "side bulge" on the shelf. Rigid boards, folding cartons, and E-flute mailers each have a specific weight limit and structural role.

Many founders ask me for the "safe material choice." The truth is, safety depends on your bottle's weight and your shipping method. Keep reading to find the exact specs you need.

Why does choosing the right skincare box material matter so much?

Picking the wrong material isn't just an aesthetic issue; it's a financial one. I’ve seen brands lose entire shipments because the board was 0.2mm too thin.

Material choice is your first line of defense against "logistics violence." Heavy jars and glass bottles need strong fibers (like virgin pulp SBS) and stable locking structures, not just a pretty print.

Material Options

You don't need to be a paper engineer, but you do need to know why a 100-unit trial run (which we always recommend at Packzino) can save you thousands in damaged returns. I once saw a client upgrade from 300gsm to 350gsm cardstock, and their "corner crushing" rate dropped from 12% to 0%. Let’s review the options with a clear, factory-floor lens.

How product weight affects material choice

Heavy products push the box walls outward.

- Lightweight (Serums < 30g): Standard 300gsm cardstock works fine.

- Heavyweight (Cream Jars > 50g): If you put a heavy jar in a weak box, the bottom will fall out. You need a reinforced "snap-lock bottom" or a rigid box structure.

How shipping method changes the requirements

- Air Shipping: High pressure and stacking. Boxes need strong vertical compression strength.

- Sea Shipping: High humidity. Standard paper absorbs moisture and gets soft ("soggy box syndrome"). We recommend UV coating or lamination to seal the fibers.

Material Failure Table

| Product Type | Common Failure | Factory Fix |

|---|---|---|

| Glass serums | Panel denting | Upgrade to 350gsm or add internal corrugated liner |

| Cream jars | Bottom collapse | Switch from auto-lock to crash-lock bottom |

| Toners | Side bulge | Increase paper caliper (thickness) or change grain direction |

| Gift sets | Insert shifting | Tighten die-cut tolerance to 0.5mm |

Material is not just a cost item. It is the structural skeleton of your product.

Is rigid paperboard the best choice for premium skincare boxes?

Premium skincare often uses rigid boxes (set-up boxes) 1, not just for looks, but for the "sound."

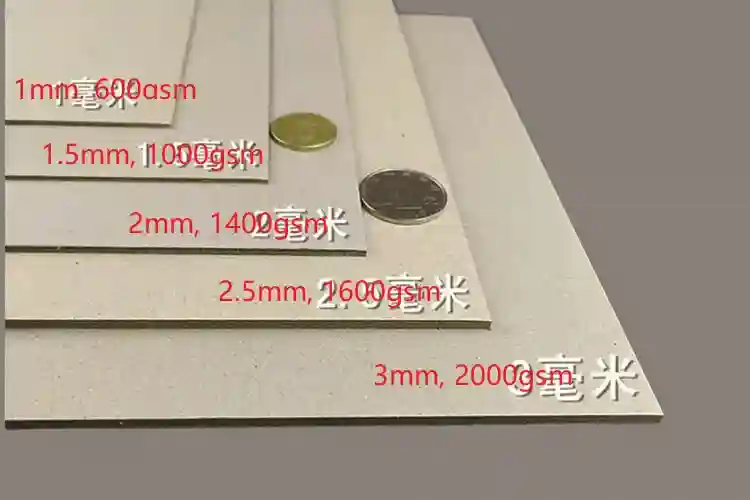

If you want that satisfying "thud" sound when a customer closes the box—like an iPhone box—standard cardstock won't do. You need 1200gsm greyboard wrapped in 157gsm art paper.

RIGID BOARD THICKNESS

I often recommend rigid board when brands use heavy jars or fragile glass.

For a recent client launching a $100 night cream, we used V-grooving technology on the rigid board. This creates sharp 90-degree corners, making the box look crisp and expensive, unlike the rounded edges of cheaper machine-made boxes.

One Canadian client originally used 1.2 mm board for heavy jars to save cost. Half the boxes arrived crushed. We rebuilt it with 1.8 mm high-density board. They never had damage again.

Recommended Thickness Levels

| Product | Board Thickness | Why We Recommend This |

|---|---|---|

| Small serums | 1.2–1.5 mm | Standard rigidity, lower shipping weight |

| Cream jars | 1.5–1.8 mm | Prevents wall bowing under heavy pressure |

| Gift sets | 2.0–2.5 mm | Maximum protection for multi-item weight |

Best use cases for rigid board

- Luxury skincare lines ($50+ MSRP)

- PR Kits & Influencer boxes

- Retail display packaging (needs to stand perfectly straight)

- Fragile glass items

Rigid board offers the highest protection. It delivers the "unboxing weight" that justifies a higher price point.

When should skincare brands choose folding cartons?

Folding cartons are the workhorse of the skincare industry. They are lightweight, store flat, and cost-effective.

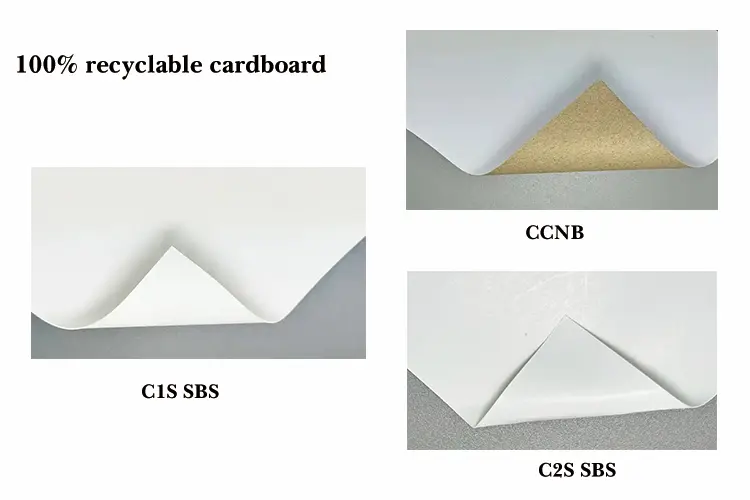

For startups ordering 500 units, standard SBS (Solid Bleached Sulfate) paper 2 is usually the best entry point—it’s pure white throughout and holds ink beautifully without color shifts.

AUTO-BOTTOM FOLDING CARTON

A common mistake I see: a brand picks 300gsm paper for a tall 100ml toner bottle. The result? The box bows out at the sides.

For anything over 80g in weight, we always reinforce the structure or bump it up to 350gsm or 400gsm.

One Japanese brand used 250 gsm C1S (coated one side) 3 for a cream jar, and the boxes collapsed in storage. We upgraded to 350gsm C1S with a matte lamination. The lamination added extra structural tension, and the problem disappeared immediately.

Recommended GSM choices

| Carton Type | GSM | Best Use |

|---|---|---|

| SBS (Virgin Pulp) | 300–350 gsm | Premium serums, best for vibrant printing |

| C1S (Coated 1 Side) | 300–400 gsm | The industry standard for most cosmetic boxes |

| Kraft (Brown) | 250–350 gsm | Eco-friendly look (Requires UV print for best results) |

When folding cartons make the most sense

- High-volume retail (shelf space is limited)

- Budget-conscious launches

- E-commerce brands using sturdy outer mailers

- Clean beauty lines needing simple, recyclable packaging

Folding cartons help reduce costs, but never go below 300gsm for skincare products unless the bottle is tiny.

Should skincare brands use corrugated boxes for shipping protection?

Don't confuse shipping boxes with ugly brown mover boxes. In 2025, the "Mailer Box" is part of the brand experience.

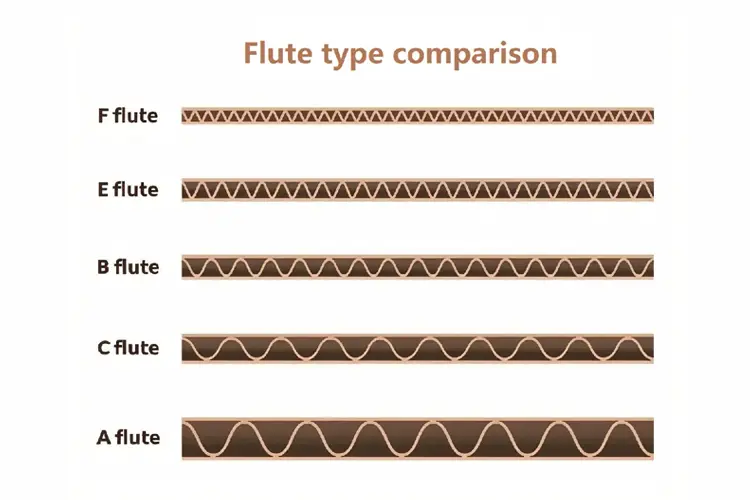

Corrugated flutes (specifically E-flute) 4 provide the perfect balance: tough enough to survive a drop test 5, but smooth enough to carry high-quality print.

FLUTE COMPARISON

I worked with a Melbourne skincare brand that had a 12% breakage rate during air freight.

Their solution was not thicker inner cartons.

The breakthrough came from switching to E-flute mailers with a custom die-cut insert. The insert locked the glass dropper in place, creating a "buffer zone" of air around the product. Even if the outer box got dented, the bottle inside stayed untouched. Breakage dropped to 0%.

Flute type guide

| Flute | Thickness | Use Case |

|---|---|---|

| F-flute | ~1.1mm | Very thin, looks like thick cardstock. Good for small retail boxes. |

| E-flute | ~1.5mm | The Gold Standard. Best for subscription boxes & mailers. |

| B-flute | ~3.0mm | Heavy shipping cartons (usually for bulk transport). |

When corrugated is essential

- Subscription boxes (Monthly kits)

- Direct-to-consumer (DTC) shipping

- Heavy multi-item gift sets

- Brands that want to print inside the box (unboxing surprise)

Corrugated is the hidden hero behind safe e-commerce delivery.

Are eco-friendly materials reliable for skincare packaging?

Eco materials attract clean-beauty consumers, but they can be a nightmare for printing if you don't know the tricks.

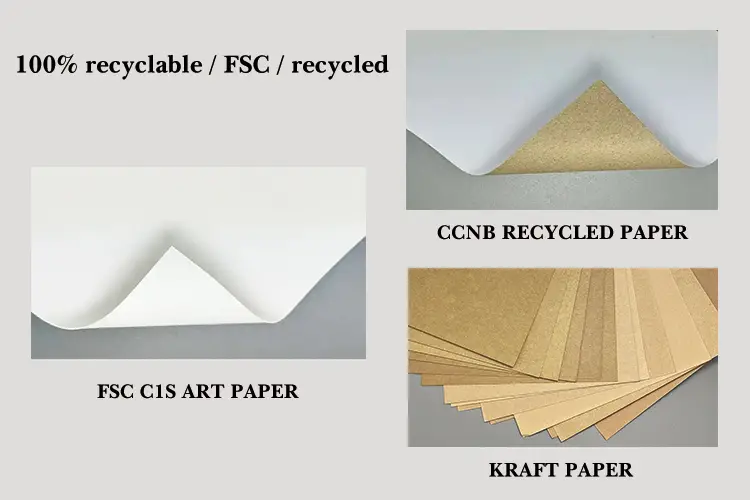

Kraft, recycled board, and molded fiber 6 are stable options, but remember: recycled fibers are shorter and weaker than virgin pulp 7.

ECO-FRIENDLY MATERIALS

Brands often think eco materials are cheaper. In reality, printing on brown Kraft paper sucks up ink like a sponge. If you use standard CMYK files, your logo will look muddy.

At Packzino, we use White Ink Underprinting—we print a layer of white ink first, then print your color on top. This makes the design pop even on dark recycled paper.

I once helped a Singapore brand solve a faded print issue on kraft paper just by adjusting the ink density and adding that white base layer.

Eco options overview

| Material | Strength | Factory Note |

|---|---|---|

| Brown Kraft | Strong fibers | Needs UV print or white ink base for bright colors |

| 100% Recycled White | Medium strength | May have small "specks" (impurities), which adds to the eco-look |

| Bagasse (Sugarcane) | Soft feel | Great for molded inserts, replaces plastic trays |

When eco performs best

- Minimalist design (1 or 2 colors)

- Organic skincare brands

- Brands that can accept "natural imperfections" in the paper texture

Eco materials work well, but you must design for the material, not against it.

Conclusion

Choose materials based on weight, shipping needs, and brand position. But don't guess.

Not sure if your jar is too heavy for 300gsm paper? Send us the dimensions. At Packzino, we can mock up a plain sample in 3 days so you can test the fit, feel, and "shake test" before spending a dime on bulk production.

-

Learn what's the rigid box and how to make them ↩

-

Read the official technical definition and properties of this premium white paper grade and usage. ↩

-

Understand what is the C1S paper and the benefits. ↩

-

Choosing the Right Corrugated Flute Type and learn their affection. ↩

-

View the official international standards used for packaging safety and drop testing. ↩

-

Explore how molded pulp inserts offer a sustainable, plastic-free alternative for protection. ↩

-

Understand the official definition of virgin pulp,and enhance confidence in distinguishing it from recycled pulp. ↩