I once met a pastry chain owner who thought paper bags were all the same—until 500 of their boxes had to be repacked overnight because the handles tore.

Choosing the right handle—twisted, flat, die-cut, rope, or ribbon—decides how your bags perform under real use and how your brand feels in customers’ hands.

The right handle keeps your packaging strong and environmentally responsible 1, attractive, and cost-efficient. Here’s how I explain handle choices to visiting clients at our factory.

Why do twisted paper handles suit most retail and bakery brands?

Every month, I meet small bakery or skincare brands who underestimate how much pressure their bags take. One client once used weak handles for pastries and got complaints within three days.

Twisted paper handles are durable, recyclable, and ideal for medium-weight bags used by bakeries, skincare shops, or gift stores.

TWISTED HANDLE

In our workshop, we roll paper cords on a Heidelberg gluer. Each cord passes a tension test before we glue it inside the bag.

We usually keep the glue line hidden, giving the surface a cleaner look and higher pull strength.

For one Japanese café chain, these twisted handles passed an 8–10 kg lift test—strong enough for pastry boxes and takeaway coffee.

Key comparison: twisted vs. flat handle for bakery use

| Feature | Twisted Paper Handle | Flat Paper Handle |

|---|---|---|

| Strength | 8–10 kg | 5–6 kg |

| Comfort | Medium grip | Softer grip |

| Eco-friendly | 100% paper, recyclable | 100% paper, recyclable |

| Best for | Pastry shops, skincare bags | Light gift or event bags |

We often color-match twisted handles to the bag’s body paper. That detail may sound small, but when the shade blends perfectly, the whole bag looks custom-made—something retail buyers always notice.

When should flat paper handles be your first choice?

Many event organizers or hotels prefer speed and cost control over maximum strength.

I remember a local hotel promotion that needed 20,000 giveaway bags in one week—flat handles saved their deadline.

Flat paper handles and their manufacturing benefits 2 are affordable, fast to produce, and suitable for takeaway or promotional paper bags.

Flat Paper Handle Bag Production Line

Our flat-handle machines run at nearly 200 bags per minute. This makes them ideal for large-volume, quick-turn projects.

However, a skincare buyer once ignored my warning and used flat handles for 300 ml glass jars—the first batch failed an 8 kg tension test.

Since then, I’ve always said: use flat handles for speed, not for strength.

Strength & cost comparison

| Handle Type | Cost per 1,000 pcs | Load Capacity | Production Speed |

|---|---|---|---|

| Twisted Paper | +10% higher | Medium-heavy | Medium |

| Flat Paper | Standard | Light-medium | Fastest |

Flat handles are perfect for bakery boxes, brochures, or hotel room gifts. They reduce lead time by about 25% compared to twisted handles. For most promotional projects, that’s the difference between “ready in time” and “missed the event.”

Why are die-cut paper handles popular for promotional and event bags?

At first, die-cut handles look modern and neat—but they need the right reinforcement.

A Singapore hotel once ordered 10,000 die-cut bags for an expo. The first samples tore when loaded with bottled amenities.

Die-cut handles offer sleek design and functional benefits 3, space-saving, and ideal for light products or short-term promotional use.

DIE-CUT HANDLE

We solved the tearing issue by laminating a hidden kraft patch behind each cutout. The change added only $0.03 per bag but doubled the tear strength of reinforced paper bags 4.

Now, the same hotel orders the same design every season, confident in its reliability.

Die-cut handle pros & cons

| Category | Pros | Cons |

|---|---|---|

| Appearance | Sleek, minimalist | No external texture |

| Storage | Saves space | Limited for heavy goods |

| Strength | Moderate with reinforcement | Weak without patch |

| Use Case | Hotel promos, flyers, brochures | Heavy skincare boxes |

For die-cut styles, we typically recommend 210–250 gsm paper and rounded edges to prevent hand strain. They stack flat, which saves freight volume—something large retailers really appreciate.

How do rope and ribbon handles elevate your packaging?

When brands aim for a luxury image, nothing replaces a tactile handle. I’ve seen many clients upgrade from twisted to rope or ribbon after touching samples once.

Rope and ribbon handles offer the most premium feel, perfect for high-end skincare, fashion, or corporate gifting.

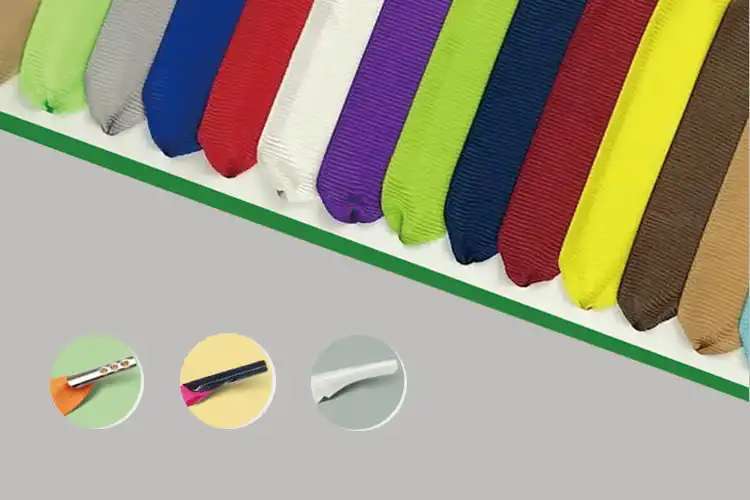

Satin Ribbon HANDLES

Rope handles can be cotton, nylon, or PP. When knotted or riveted properly, they hold 10–15 kg easily. Ribbon handles—often satin or grosgrain—bring a soft, elegant feel.

When we supplied a Toronto skincare brand, their old glossy twisted handles reflected harsh store lighting. We switched to matte satin ribbons in their Pantone tone—smoother to touch, no glare under LED.

Their social media post featuring the new bags tripled engagement that week, and they reordered 5,000 more.

Rope vs. Ribbon handles

| Feature | Rope Handle | Ribbon Handle |

|---|---|---|

| Strength | 10–15 kg | 5–8 kg |

| Texture | Firm, durable | Soft, elegant |

| Branding | Neutral or sporty | Luxury or feminine |

| Best For | Skincare sets, candles | Boutique gifts, cosmetics |

These handles take longer to assemble because each must be threaded or riveted by hand. But when clients visit our production floor and see the craftsmanship, they immediately understand why premium brands insist on them.

How can you choose the right handle for your business?

After 15 years in packaging, I’ve noticed the same pattern: buyers choose handles by looks, not by load. One European buyer once told me, “We never thought 2 cm of paper could cause this much trouble”—until half their bags failed at a Christmas fair.

Choosing a paper bag handle should start from packaging weight and load testing standards 5, then style, then cost—not the other way around.

HANDLE SELECTION GUIDE

At Packzino, every new client’s product goes through a quick tension check—double their product weight.

Only after that do we suggest handle types and confirm with color or texture samples.

| Industry | Product Example | Recommended Handle | Why |

|---|---|---|---|

| Bakery | Pastry boxes, coffee cups | Twisted paper | Strong, recyclable, budget-friendly |

| Skincare | Serum sets, cream jars | Rope or ribbon | Premium look, soft grip |

| Hotel promo | Amenity kits, brochures | Flat or die-cut | Lightweight, easy stacking |

| Food takeaway | Lunch boxes | Flat paper | Fast production, low cost |

| Corporate gifts | Premium gifts | Ribbon handle | Luxury appeal |

I always tell buyers: before placing a large order, grab a sample and lift it by hand. If it doesn’t feel safe with twice the expected weight, adjust the design now—it will save thousands later.

FAQs About Choosing Paper Bag Handles

Q1: What factors determine the best handle for paper bags?

The best handle depends on weight, purpose, and brand image. Heavy items need twisted or rope handles; flat or die-cut handles work for lightweight, short-term promotions. Always balance function with the look your customers expect.

Q2: What is the strongest handle for paper bags?

Rope handles are the strongest option, tested to hold 10–15 kg when properly knotted or riveted. They’re ideal for skincare gift sets, candles, and premium retail packaging that needs both durability and elegance.

Q3: Are paper bag handles eco-friendly?

Yes. Twisted and flat handles are 100% paper and recyclable, while rope and ribbon styles can be reused for gifts. Choosing FSC-certified paper or cotton ropes further supports sustainable packaging goals.

Q4: Can I customize handle colors and materials?

Absolutely. Most packaging factories, including Packzino, offer Pantone color matching and multiple materials—such as cotton, nylon, PP rope, or satin ribbon—to match your brand’s tone and packaging style.

Q5: Why do paper bag handles break easily?

Handles often break due to low GSM paper, weak glue adhesion, or overloading. Always test your bag with double the expected weight and ensure proper reinforcement for die-cut or glued-in handles before mass production.

Conclusion

Handle choice reflects more than design—it’s proof of your brand’s reliability. Test it, match it, and your packaging will always speak quality before your product does.

-

Discover effective methods to strengthen your packaging, ensuring it meets customer expectations and reduces costs. ↩

-

Explore the advantages of flat paper handles, including cost-effectiveness and speed, which are crucial for event organizers. ↩

-

Explore the benefits and design considerations of die-cut handles for promotional bags, enhancing your marketing strategy. ↩

-

Learn effective methods to enhance tear strength in die-cut bags, ensuring durability and reliability for your products. ↩

-

Understanding weight testing is crucial for ensuring your packaging can handle the intended load, preventing costly failures. ↩