Many buyers feel lost when suppliers casually claim “eco-friendly.” Real standards matter, not slogans. Let’s uncover what makes packaging truly sustainable.

A box is eco-friendly when its materials, certifications, and lifecycle all meet sustainability standards, from raw fiber sourcing to end-of-life recycling.

Claims alone are not enough. Real eco-packaging needs proof. Keep reading below.

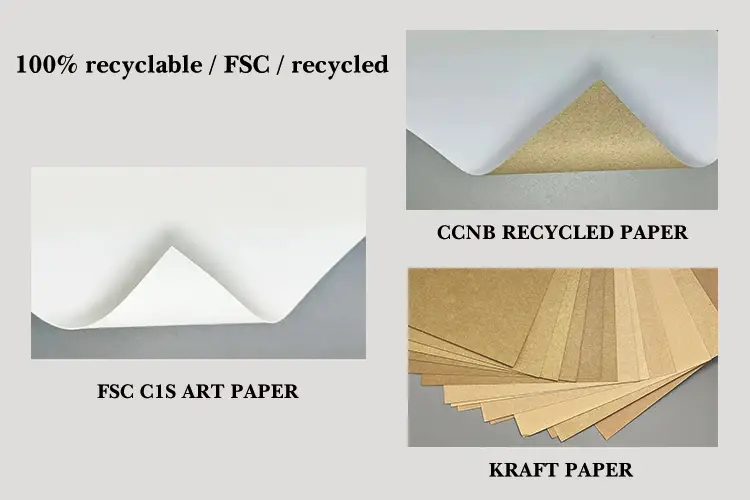

Which materials define an eco-friendly packaging box?

Eco-friendly packaging materials include kraft paper, FSC-certified virgin fiber1, recycled paperboard, soy inks2, and water-based coatings. Each brings unique benefits and trade-offs.

FSC, recycled, and kraft paper materials

In practice, many brands think recycled paper is their only option. But in our factory, we’ve seen how the right material depends on the product and market.

For example, a skincare brand insisted on kraft for its “natural” look but later realized it didn’t fit their luxury positioning. We switched them to coated FSC board, which not only passed EU audits but also looked premium on shelves.

👉 Extended Reading: Sustainable packaging trends – Packaging Europe3

Comparing common eco-materials

| Material | Eco Benefit | Limitation | Typical Use |

|---|---|---|---|

| Kraft Paper | 100% recyclable, rustic look | Not ideal for luxury branding | Food, e-commerce |

| FSC Certified Board | Sustainable virgin source | Slightly higher cost | Cosmetics, premium |

| Recycled Paperboard | Reduces virgin fiber demand | Lower stiffness | Inserts, inner boxes |

| Water-based Coating | Easier to recycle | Limited glossy finish | Skincare, food-safe |

Material choice shows eco-friendly is not one-size-fits-all. Small skincare brands may start with kraft for authenticity, while premium markets demand coated FSC board.

Why do certifications matter when choosing sustainable boxes?

Certifications like FSC1, PEFC4, EN134325, or ASTM D64006 prove packaging sustainability and safety. They help brands meet import and retail compliance requirements.

Eco-Packaging Certifications

Certifications are not just paperwork—they decide whether shipments clear customs or get delayed. One food client of ours had boxes stuck in Germany for weeks because they lacked EN13432 proof. After we helped them add the right certifications, their next shipment entered EU retail smoothly.

👉 Extended Reading: Top Eco Friendly Packaging Trends 2023 – PakFactory Blog7

Key certifications buyers should check

| Certification | Scope | Benefit |

|---|---|---|

| FSC / PEFC | Forest management | Verifies sustainable paper sourcing |

| EN13432 | Compostability | Required for EU compostable claims |

| ASTM D6400 | Compostability | North American standard compliance |

| FDA / EU Food Safety | Food contact | Safe for direct contact packaging |

When sourcing, always request valid certificates. In our experience, brands with proper documentation gain trust from retailers faster, while uncertified claims often face rejection.

How does lifecycle analysis define true eco-friendly packaging?

Lifecycle analysis8 evaluates raw materials, energy use, transport, product use, and recycling. Eco-friendly packaging reduces total environmental impact, not just at one stage.

lifecycle diagram

From what we see in production, lifecycle matters more than just the type of paper. A recycled board box shipped 10,000 km with plastic lamination can have a bigger footprint than a locally made FSC box with water-based inks.

That’s why we often remind clients: eco-friendly isn’t about one material—it’s about the whole journey.

👉 Extended Reading:The ultimate guide to food packaging sustainability – EIT Food9

Key lifecycle stages to evaluate

| Stage | Questions to Ask |

|---|---|

| Raw Materials | Virgin or recycled? Certified source? |

| Production | Energy efficiency? Waste control? |

| Printing & Finishing | Water-based inks or plastic films? |

| Logistics | Light-weight design to reduce shipping? |

| End-of-Life | Recyclable or compostable in buyer’s market? |

Lifecycle thinking helps companies balance eco-goals with real-world logistics. For example, a lighter corrugated shipper may cut transport emissions even if it’s not made from recycled fiber.

What should buyers ask before sourcing eco-friendly boxes?

To confirm eco-friendly packaging, ask for certifications, material specs, small-batch samples, and recycling instructions before ordering.

Kraft Packaging Box Applications

Before placing an order, we always suggest buyers request real certificates and do a small trial run. For instance, one Japanese customer tested our FSC box samples in their local recycling stream before confirming a 50,000-unit order. This small step saved them from compliance risks later.

👉 Extended Reading: FDA food contact packaging10 | EU food contact materials11

Buyer checklist for eco-friendly packaging

- Certification proof: FSC, EN13432, FDA, EU food contact

- Material declaration: recycled %, coatings used

- Sample availability: small-run test before mass order

- Recycling instructions: guidance for end-users

- Lead time and logistics: confirm eco goals do not delay market launch

FAQs

Are eco-friendly boxes more expensive?

Not always. Kraft and recycled paperboard can be affordable, while FSC or compostable materials may cost slightly more but add brand value.

Can small brands order eco-friendly packaging in low quantities?

Yes. With digital printing and flexible suppliers, you can start from 100 units to test designs before scaling up.

How do I know if my box is recyclable?

Check with your local recycling program. Generally, kraft and paperboard without plastic films recycle easily, while laminated or foil boxes may not.

How can small brands test eco-packaging before committing?

We suggest starting with small MOQ trial runs. One Japanese buyer tested FSC samples in their recycling system before confirming 50,000 units—saving time and risk later.

Eco Packaging Production Process

Conclusion

Eco-friendly packaging requires certified materials, lifecycle awareness, and proof—balancing sustainability, compliance, branding, and cost efficiency.

-

Learn how soy-based inks differ from traditional inks in eco performance. ↩

-

View Europe’s sustainable packaging trends and policy updates. ↩

-

Understand how PEFC forest certification works. ↩

-

Learn about EU’s compostability standard for packaging. ↩

-

Explore North America’s compostable packaging standards. ↩

-

Read industry insights on trends in eco packaging. ↩

-

Dive into the LCA (life cycle assessment) framework. ↩

-

Explore sustainability challenges and solutions in food packaging. ↩

-

Verify US regulations for food contact packaging. ↩

-

Understand EU’s rules for food contact materials. ↩