Many small brands get frustrated when packaging quotes aren’t clear. Hidden fees show up late, cut into profit, and delay product launches.

Most folding cartons 1 cost between $0.30 and $1.50 per unit, depending on board grade, size, printing, quantity, tooling, and shipping.

If you know where the money goes, you control your budget. Let me share what I have seen in real orders.

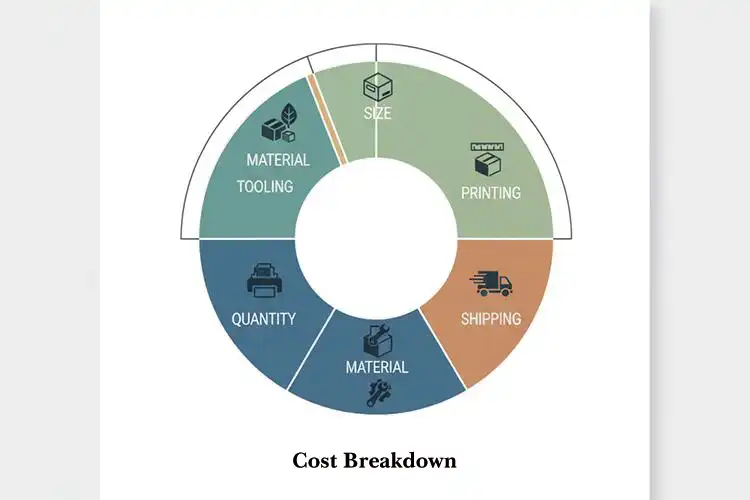

What Factors Decide the Price of a Custom Folding Carton?

The first time I ordered folding cartons, I honestly thought the price was random. Later I realized details like board weight, carton size, and even shipping choice could make the price jump much more than I expected.

The key drivers are board grade, carton size, printing and finishes, order quantity, tooling, and shipping method.

Cost Breakdown Overview

Paperboard grade is always the first question. A 250g board looks fine for light items, but a 350g coated stock 2 gives more strength and a premium surface. Size is another lever. Small cartons use less board, but odd shapes can waste material.

Printing choices matter. One-color offset is simple, while CMYK 3 plus spot UV raises cost. Special finishes like foil stamping or embossing make cartons stand out, but they bring new setup charges. Order quantity changes everything. A run of 300 cartons carries the same printing fees as 2,000, so the unit price rises fast on small orders.

Tooling adds one-time costs if you want a window or a non-standard cut. Shipping is the final piece. I once compared air freight versus ocean freight on the same job; air doubled the unit cost, but the client needed it fast.

Quality vs Cost

Many buyers think thicker board automatically means better. But for lightweight products, going too heavy just wastes money. Buyers need to balance brand image with actual protection for the product.

| Question | Option A (Low Spec) | Option B (High Spec) | Dialectical Point |

|---|---|---|---|

| Paperboard Thickness | 250gsm, cheaper | 350gsm, premium | More is not always better. Balance strength with need. |

| Carton Size | Compact, less waste | Oversized, more protection | Extra space adds shipping cost without clear benefit. |

| Printing | One-color economy | Full CMYK with finishes | Rich design boosts branding but raises unit cost. |

Which Costs Are Visible and Easy to Estimate?

Some costs are clear from the start. They show up on every supplier’s quote.

Visible costs include board, printing, lamination, and assembly. They rise or fall directly with order quantity.

Visible Cost Items

When I get requests from clients, the first numbers I show are material and printing. If you choose kraft paper, you see that in the quote. If you want four-color CMYK, the supplier notes that too. Finishes like matte lamination or gloss coating are also visible. Assembly is another one—cutting, folding, gluing—clearly added in unit cost. These visible costs are what most buyers expect. They are the easy part to compare across suppliers.

Transparency vs Oversimplification

Visible costs look simple, but simplicity can mislead. A supplier might quote only unit price without noting minimums, or list material without explaining durability. Transparency is a good start, but buyers should still dig deeper into what those line items really mean.

| Visible Cost Item | What It Shows Clearly | What It Hides If Ignored |

|---|---|---|

| Material | Thickness, type | Impact on product strength and shipping |

| Printing | Number of colors | Setup plate fees, ink coverage surprises |

| Lamination | Finish type | Long-term durability, scratch resistance |

| Assembly | Folding and gluing | Effect on box strength under real stress |

What Hidden Fees Do Many Buyers Overlook?

This is where most of the surprises come from. Buyers rarely see them until it is too late.

Hidden fees include die-cut tooling, plate setup, sample proofing, rush order surcharges, and extra shipping charges.

Hidden Fee Examples

I remember a client who ordered 500 shipping cartons for a skincare launch. The per-unit price looked fine. Later the supplier added $50 for tooling and $65 for plate setup forflexographic printing.

On top of that, a rush order fee pushed the budget over the edge. Proofing charges also catch people. A plain white sample is usually free, but a printed sample with foil may cost extra.

Shipping is another trap. Customs, last-mile delivery, or even fuel surcharges sneak into the final invoice. One client even faced storage charges because the cartons sat too long in the warehouse.

Are Hidden Fees Always Negative?

Most buyers see hidden fees as unfair, but in reality, some of them cover real costs suppliers can’t avoid—like tooling or rush orders. Tooling is a one-time investment. Rush orders disrupt production. The problem usually isn’t the fee itself—it’s whether the supplier explained it up front.

| Hidden Fee Type | Why It Exists | Buyer’s Risk if Ignored | Balanced Approach |

|---|---|---|---|

| Tooling | Custom die creation | Unexpected upfront expense | Ask for transparency; reuse if repeat |

| Plate Setup | Printing preparation | Extra charge on new artwork | Budget once, reuse for reprints |

| Rush Orders | Overtime, priority scheduling | Sharp cost increase | Plan early, reserve buffer time |

| Logistics | External duties, surcharges | Higher landed cost | Confirm Incoterms before signing |

How to Avoid Extra Charges When Ordering Folding Cartons?

The good news is, you can protect yourself with a few simple steps.

Ask for itemized quotes, confirm tooling, discuss sample policies, and clarify shipping terms early.

Practical Cost Checklist

I've been in the packaging and printing industry since 2019, and with every inquiry I receive, my quotation lists the possible costs, to make it easy for the customer to verify the final cost.

Shipping terms are also critical - FOB, CIF, or DDP 4 have different responsibilities and costs. The most trustworthy suppliers offer immediate transparency, and some even offer free design support and low MOQs, which can be beneficial to new brands as they test the market.

Proactive vs Reactive Buyer

It’s tempting to just react when problems come up. But buyers who ask early questions usually get better deals—and even faster service.

| Buyer Style | Behavior | Result |

|---|---|---|

| Reactive | Accepts quotes as given | Faces surprise charges later |

| Proactive | Demands itemized details upfront | Gains clarity, avoids hidden fees |

FAQ: Folding Carton Cost Questions Buyers Often Ask

Over time, I noticed clients ask the same questions again and again. Clear answers save them worry.

FAQs usually focus on small order pricing, setup fees, shipping impact, special finishes, and cost-saving ideas.

Buyer FAQ on Folding Carton Costs

How much does 100 custom folding cartons cost for small brands?

100 custom folding cartons usually cost $150–$200, depending on board thickness and printing.

Can shipping cost more than the folding cartons themselves?

Yes, for small air-freight orders, shipping can cost more than the cartons. Ocean is cheaper but slower.

Do premium finishes increase folding carton cost significantly?

Yes. Premium finishes like foil, emboss, or spot UV often add $30–$45 setup on runs under 1,000 units.

How can I lower my total carton cost?

You can lower carton cost by ordering slightly more, choosing standard sizes, and confirming shipping terms early.

Are samples free?

Unprinted white samples are usually free; custom printed samples with finishes cost extra.

FAQs give quick answers, but real situations can be more nuanced—for example, ‘samples are free’ often means only unprinted ones.

Conclusion

Folding carton pricing always includes both obvious and hidden elements. Buyers who raise key questions early are the ones who avoid costly surprises.

Update Log

- 2025-10-02 – FAQ section updated with clear, one-sentence answers to reflect real buyer queries (small order pricing, shipping, samples).

- 2025-10-02 – Language refined for clarity and readability, making the guide easier for new buyers to follow.

- 2025-10-02 – Cost breakdown examples enhanced with practical scenarios to show trade-offs between board grade, finishes, and shipping choices.

📌 We keep this guide regularly updated so small and growing brands can rely on it as a practical resource when budgeting and sourcing folding cartons.

-

Learn what folding cartons are, their history, and how they are typically manufactured. ↩

-

Understand different paperboard types, their strength levels, and how they affect packaging. ↩

-

Learn how CMYK printing works compared to spot colors and why it impacts cost. ↩

-

Understand Incoterms like FOB, CIF, and DDP, and how they affect total landed cost. ↩