Small brands often tell me their first carton quote looked simple—until extra fees showed up later and ate into margins. Let’s look at what actually goes into a 100-unit order 1.

The cost of 100 custom folding carton order depends mainly on board material, printing, finish, setup, shipping, and lead time.

From production experience, even small decisions—such as board thickness or courier method—can shift total cost by 20–40%. The brands that plan these details early avoid last-minute surprises and keep budgets stable.

What parts make up the cost of a 100-unit folding carton order?

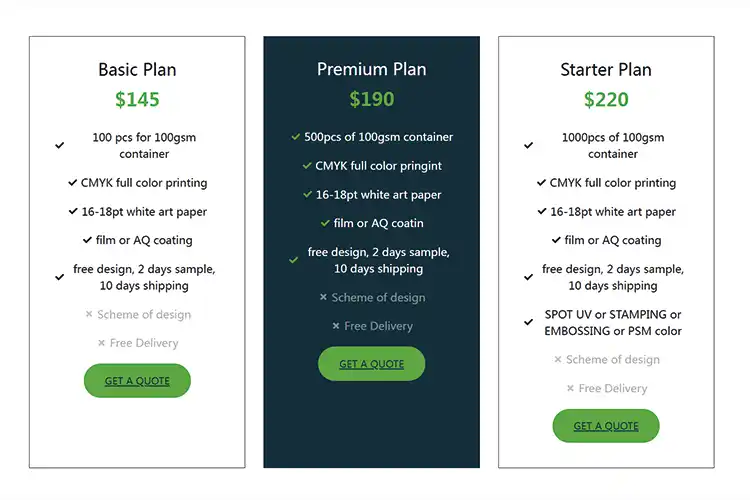

A 100-unit folding carton order is priced by five main parts: Material, printing and finish, design setup, structure complexity, and shipping or lead time.

Many buyers focus only on paperboard, then realize later that printing, setup, and courier fees can add 30–50% to the total. Based on factory records, here’s how each part typically shows up in a real quote.

Cost Components

We always start cost reviews with materials and certifications, since they form the foundation of every project. In small runs (MOQ = 100 units, 12-day lead time), board grade, thickness, and FSC certification 2 decide the baseline cost. Premium or eco boards look great but can raise total spend by 30–40%.

TNext comes printing and finishing. Colour count, soft-touch coating, or foil stamping all change plate setup and press time. Design and sampling add dieline and proofing costs, while complex structures require more glue lines and folding passes.

Shipping and lead time complete the picture: heavier boards raise freight, and urgent runs mean overtime or express courier surcharges.

In practice, these parts overlap. Heavy material lifts freight bills; complex finishes extend press time; intricate structures create waste. Knowing this early helps you choose where to spend and where to save.

For example, one dessert brand picked eco board plus full-colour print with spot UV. Material and finish together nearly doubled the packaging cost—but improved shelf presence enough to justify a small retail price bump.

Understanding these trade-offs keeps projects on budget without losing the brand look.

How does material grade & thickness change cost per box?

Thicker or eco-certified boards can raise folding carton cost by 30–40%, mainly through higher material and freight charges.

Some brands cut cost by choosing the lightest board—but boxes then bend easily or lose shelf appeal. The key is matching board strength with product weight and brand position.

Paperboard Comparison

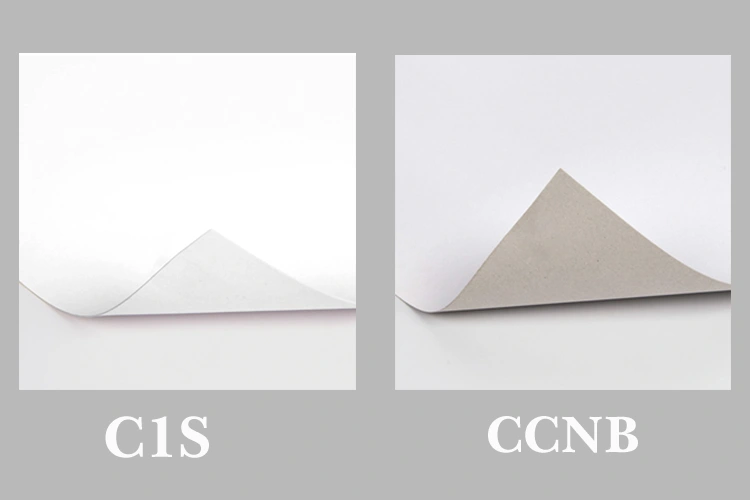

I compare three board types with thickness 3 levels. I show how cost, weight, and print outcome change.

Material Comparison Table

| Board Type | Thickness / Weight | Benefit | Drawback / Extra Cost |

|---|---|---|---|

| Standard Coated (SBS / C1S) | ~16-18 pt | Good print, smooth finish, strong enough for many cosmetic/food products | Less rigidity, more prone to moisture; print may need extra coating |

| Eco / Premium Certified Board | ~20-24 pt, FSC or recycled | Luxury feel, better rigidity, eco appeal, possibly food safety credentials | Higher material cost (30-50% more), heavier, shipping cost rises, waste trim increases |

| Kraft / Uncoated / Recycled Board | Similar or slightly thicker | Rustic or natural style; perceived eco value; often lower cost for finish | Colour less vivid; more warping risk; less protection |

From small-batch projects we’ve handled, materials usually account for about 35–50% of the total cost. In our projects, switching from standard to certified or thicker board has typically raised material cost by around 30–40%.

Also, heavier board increases shipping cost even more. Material waste from die-cut trim often increases with board thickness.

For moisture-sensitive or premium-positioned products, thicker or certified boards are worth the investment. For standard SKUs, coated paperboard with clean printing gives a better cost-to-value balance.

In my own early project, we used premium board for the hero product line but stayed with standard C1S for everyday items—keeping brand image consistent without overpaying.

Knowing when to upgrade material saves money without compromising product perception.

How much does printing and finish add to cost?

Printing method and surface finish can increase folding carton cost by 20–60%, mainly due to extra setup and production steps.

Buyers often underestimate how much finishes affect both price and timeline. Each added process—foil, embossing, or UV—requires separate setup and curing time, which can extend lead time by several days.

Finishing Types

Colour printing already varies by complexity: extra colours or metallic inks raise ink and plate cost. Adding premium finishes—like soft-touch, foil, or spot UV—multiplies setup and labour. Below is a quick reference from our production data:

| Finish Type | Extra Cost % Over Basic 4-Color Printing | Extra Lead Time (Days) | Best Use Case |

|---|---|---|---|

| Basic 4-color CMYK | baseline | +0–1 day | everyday packaging, faster orders |

| Matte or Gloss Lamination | +10–25% | +1–2 days | retail beauty or food boxes needing smooth finish |

| Spot UV / Gloss Spot | +20–40% | +1–3 days | highlight logo or text for shelf contrast |

| Foil Stamping / Embossing | +30–60% | +2–4 days | luxury SKUs, gift editions, boutique branding |

In one 100-unit cosmetic project, the client chose soft-touch coating plus gold foil. It raised cost per unit by roughly 25% but improved photo appeal so much that their sell-through rate justified the upgrade.

As a rule of thumb: use premium finishes for your hero SKUs or gift lines, where perceived value matters most. For refills or online-only packaging, a clean matte or gloss lamination achieves a professional look at lower cost.

Smart finish selection helps brands balance visual impact, production time, and margin.

How do shipping and lead time influence total cost?

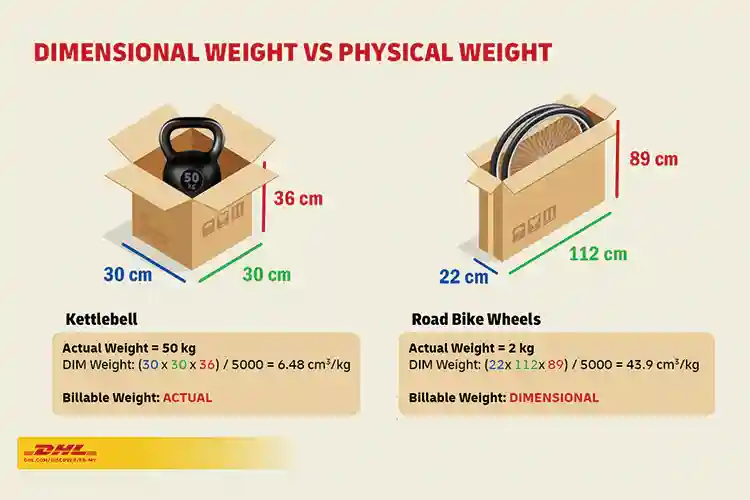

Shipping weight, box size, and rush orders are key factors that can raise total folding carton cost by 20–50%.

Many brands focus on materials and printing, only to face surprise freight bills later. Carriers charge by actual weight or by dimensional weight 4—whichever is higher. When box design wastes space, cost can double.

Shipping Factors

For small runs like 100 units, most brands choose express courier for convenience, which can add up to $50–$80 depending on box size and paper weight. Rush production adds further cost due to overtime and priority scheduling.

| Factor | Impact | How to Save |

|---|---|---|

| Board thickness | Heavier boards increase freight cost | Select the lightest grade that still protects your product |

| Box dimensions | Larger volume = higher dimensional weight | Optimize structure and internal fit |

| Shipping method | Air = fast, costly; sea = slow | Match transport to your delivery window |

| Rush production | Extra labour and machine time | Plan 2 weeks ahead to avoid rush fees |

In one food start-up project, unused internal space caused carriers to charge dimensional weight—doubling shipping cost. After redesigning a snug-fit box, we cut freight by 30%.

Another client requested a rush order during the holiday season; express production and air freight together cost more than materials.

Planning shipping and lead time from day one keeps your total cost predictable—and prevents last-minute panic before launch.

Conclusion

Carton cost is shaped by more than just paper—it’s the sum of materials, printing, structure, finishing, shipping, and timing decisions.

From factory experience, the brands that stay within budget are those that plan their specifications early, request at least two board and finish options, and review shipping methods before final approval.

Think of it as building a cost map: every choice—board thickness, coating, courier—adds a layer to the total. When those choices are made early, surprises disappear and projects stay profitable.

Smart planning at the start of production is the simplest way to cut hidden costs and protect your margin.

📑 Update Log📑

[2025-10-13] – Refined introduction for smoother tone and stronger snippet targeting.

[2025-10-13] – Rewrote cost breakdown section with clearer hierarchy (materials → printing → structure → shipping).

[2025-10-13] – Enhanced material section with quantified data and board-type table for SEO clarity.

[2025-10-13] – Updated printing & finish module with real project example and SERP-friendly structure.

[2025-10-13] – Reworked shipping & lead time section with dimensional-weight example and optimization tips.

[2025-10-13] – Simplified conclusion into actionable planning steps to close content loop.

📌 This guide is regularly updated to reflect real production insights and current factory data, helping small and growing brands budget smarter for custom packaging projects.

-

Learn real-world cost ranges for small folding carton orders, including price per unit and influencing factors. ↩

-

Learn what FSC certification means for paper packaging and why it increases cost but boosts brand credibility. ↩

-

Understand the technical differences between SBS, C1S, and Kraft boards and how each affects durability and appearance. ↩

-

Learn how dimensional weight is calculated and why it can double packaging freight costs. ↩