Many businesses struggle to choose the best printing techniques for their products. You need clarity to pick the right one.

Selecting a printing method depends on factors like material, volume, and design intricacy. Each technique offers unique advantages suited for specific needs.

printed coffee packaging boxes

Choosing a printing method can feel overwhelming. The variety of options can lead to confusion without proper guidance.

What are the most common printing methods?

The top methods include offset printing, flexographic printing, gravure Printing screen printing, digital printing, and UV printing. Each is tailored for different packaging needs.

When I first explored printing, I had trouble picking a method. Each seemed appealing, yet drawbacks became apparent during closer examination.

Komori printing facility

Offset Printing: Is it worth the investment?

Offset printing1 is a type of lithographic printing,it is ideal for high-quality results on paper packaging. It uses plates to transfer ink onto a rubber blanket and then onto the material.

Offset printing is perfect for long runs of paper-based products, offering sharp, professional graphics. However, setup costs can be high.

Advantages of Offset Printing

| Feature | Benefit |

|---|---|

| High-quality imagery | Excellent for premium branding |

| Economical for large runs | Cost per unit decreases with volume |

| Color precision | Pantone and CMYK color systems supported |

Is offset printing right for you?

Offset printing is used for foldable cartons, gift boxes, labels, and other high-quality packaging. It works best for companies needing consistency in large orders. For example, if you're producing hundreds of skincare boxes, it guarantees a flawless finish. However, if your order is FEWT TENS, digital printing might serve better in such cases.

How does flexographic printing work?

Flexographic printing is widely used for corrugated boxes, bulk tote bags, pouches, tissue paper, food wrappers, labels, and plastic films. It relies on flexible plates and quick-drying inks.

This method excels in high-speed production of packaging with basic designs, especially for non-paper materials.

Flexo printing process

Key Features of Flexographic Printing

| Feature | Description |

|---|---|

| Versatility | Prints on paper, plastic, and foil |

| Speed | Fast production rates |

| Cost efficiency | Low cost for high-volume runs |

When to choose flexographic printing?

Flexo printing shines for mass production of simple designs. For example, if you're producing bulk packaging for food or beverages, it can handle repetitive patterns and logos efficiently. However, it struggles with intricate designs or photo-realistic details. If aesthetics matter more, offset printing might suit better.

What makes gravure printing unique?

Gravure printing proces

Gravure printing2, also known as rotogravure, stands out due to its use of engraved cylinders to transfer ink directly onto the substrate. This method delivers unmatched consistency and quality, particularly for large-scale print runs. Although it requires significant initial investment, gravure printing provides unparalleled cost-efficiency for high-volume production.

Typical applications of gravure printing

-

Flexible Packaging

Gravure printing is perfect for printing on materials like plastic films, aluminum foil, or coated paper used in food and beverage packaging. It ensures vivid colors and fine details that enhance brand visibility. -

High-Volume Printing

Gravure is ideal for industries requiring millions of identical prints, such as magazines, wallpaper, and gift wrap. The engraved cylinders can be reused, making it cost-effective for long runs. -

High-Quality Labels

Premium products like luxury cosmetics, perfumes, and spirits often use gravure-printed labels for their precise design and vibrant colors.

What are the benefits of digital printing?

Digital printing offers fast turnaround times and lower costs for small orders. It directly prints from a digital file without plates.

Digital printing is ideal for customized or low-volume orders, ensuring fast results and great flexibility.

EPSON digital printing machine

Benefits of Digital Printing

| Feature | Benefit |

|---|---|

| Low initial cost | No need for plates |

| Customization | Perfect for personalized designs |

| Short run efficiency | Cost-effective for small quantities |

Why choose digital printing?

Digital printing is transformative for small businesses or seasonal products. For instance, if you're launching a limited-edition skincare set, it allows for intricate, photo-quality designs without breaking the bank. However, scaling up production can be costly per unit, making offset or flexographic printing more economical for large runs.

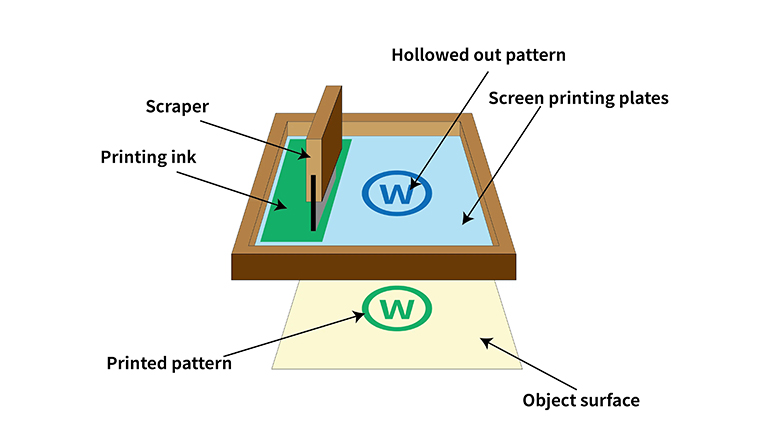

When is screen printing the best option?

Screen printing excels at bold, vibrant designs on rigid surfaces like glass or metal. It's a manual process requiring precision.

This technique is great for custom, high-impact packaging with limited runs but involves slower production speeds.

Diagram of screen printing

Pros and Cons of Screen Printing

| Advantage | Challenge |

|---|---|

| Vibrant colors | Limited to flat surfaces |

| Durable print quality | Slower than other methods |

| Ideal for rigid materials | Higher per-unit cost for small batches |

Can screen printing fit your needs?

Screen printing is perfect for high-end or artisan products. For instance, glass jars for luxury candles look stunning with bold screen-printed designs. However, for mass production, it's slower and pricier than other methods. You need to assess whether the aesthetics justify the costs.

Why is UV printing worth considering?

Struggling to get vibrant, durable, and fast-drying prints? UV printing solves your problem by providing high-quality results on various materials instantly.

UV printing uses ultraviolet light to cure ink immediately, offering sharper, long-lasting prints on paper, plastic, glass, and more for versatile applications.

Heidelbery UV printing machine 7+1colors

Scenarios where UV printing excels

-

High-End Packaging Needs

If you’re designing packaging for skincare, cosmetics, or premium gift products, UV printing ensures vibrant colors and precise details. It gives a luxurious look that reflects the quality of your brand. -

Fast Turnaround for Tight Deadlines

UV printing instantly dries ink. This eliminates waiting time and speeds up production, making it ideal when deadlines are critical. -

Printing on Unique Materials

Need to print on non-porous surfaces like plastic, foil, or coated paper? UV printing excels where traditional methods fail. It ensures ink adheres perfectly without smudging or fading.

| Best for | Why UV Printing Fits |

|---|---|

| Luxury skincare packaging | Premium, precise, and vibrant print quality |

| Plastic or foil materials | Ensures ink adhesion and durability |

| Time-sensitive projects | Instant drying reduces production delays |

| big, custom batch orders | Supports high-quality short runs effectively |

Critical considerations before choosing UV printing

Although UV printing offers significant benefits, it is not always the most economical solution. Businesses should consider:

- Cost: UV printing is pricier than traditional methods, which may not suit low-budget projects.

- Purpose: If you need basic designs or mass production without a focus on quality, traditional printing may suffice.

I really want to use UV printing for my brand, what can i do?

We have Heidelberg 5+1color and 7+1color UV printing machine, normally more than 2000 boxes can choose UV printing machine, and the price is 25-30% more expensive than normal OFFSET PRINTING. But our UV printing machine can do SPOT UV, frosted (touch is rough grainy matte effect), but also can do stamping effect, and special pattern effect, these are free, but in OFFSET PRINTING are extra charge. Generally 2000 boxes OFFSET PRINTING about 400 U.S. dollars, if you also do stamping, spot UV And frosting effect, which maybe expensive than UV printing

What should you consider when choosing a printing method?

Many factors influence your choice of printing method. Balancing quality, cost, and material compatibility is crucial.

Key considerations include material type, order size, and the complexity of your design. Always match the method to your goals.

printed packaging boxes for soap, electronics

Weighing your options

If your material is paper-based and you have large orders, offset printing makes sense. For plastic-based packaging, flexographic printing offers versatility. Digital printing shines for custom orders, while screen printing is ideal for niche markets. Each has its strengths, and understanding these ensures you get the most value.

Choosing the Right Method

| Method | Best for | Key Limitation |

|---|---|---|

| Offset Printing | High-quality, large-scale production | High costs for small batches |

| Flexographic Printing | Cost-effective, large-scale, simple designs | Limited precision, not ideal for details |

| Gravure Printing | High-volume, premium packaging with gradients | High setup costs, uneconomical for small runs |

| Screen Printing | Special effects (spot UV, metallic, embossing) | Slow production, suitable for small-scale runs |

| Digital Printing | Small batches, personalized and custom designs | Less economical for large runs, lower color saturation |

| UV Printing | High-end glossy or spot UV finishes | Slightly higher cost |

Conclusion

The right printing method depends on your product, material, and scale. Evaluate your needs to make the most cost-effective and visually striking choice.